Triazine Vs. Non-Triazine for H2S Treatment

When choosing the appropriate H2S Scavenger either for oil treatment, acid gas sweetening, mercaptan odor removal or through mechanical processes, it is essential to fully analyze the different alternatives on the market, as different products are better suited for different applications and process conditions. As our analysis will show, one may be better than the other depending on the specific conditions of what needs to be treated. Over the years, triazine-based treatment has been the go-to solution for many Producers, Midstreamers, and Refiners, and to a large extent it is still the go-to choice. But for some, implementing new technology such as non-triazine products has positively impacted their operations and has lowered their costs. Is one better than the other? That all depends on your use case and process conditions. Here you’ll find a brief description of both triazine and non-triazine alternatives to help inform you of the effective solutions on the market for your application.

Triazine Treatment

Triazine for H2S scavenging is an established and reliable chemical reaction that is employed in the Oil & Gas industry to remove H2S from gas streams. The H2S scavenging can be done via direct injection in pipelines with fog nozzles, wet scrubbers, or bubble towers at either wells, central batteries or midstream systems. The triazine scavenging technique is most cost-effective for gaseous streams with sulfur loading of less than 1000 lbs. per day. It typically reduces H2S concentrations to <4 ppm and partially removes several light mercaptans (methyl, ethyl, and propyl). Triazine’s ability to remove H2S is affected by various parameters, including temperature, pH, contact duration, and natural gas composition. The final product is water soluble and is usually discharged in the produced water tanks and commercial saltwater disposal facilities.

It is important to note that using triazine as an H2S scavenger may cause fouling from the polymerization of dithiazine in contact towers, scrubbers and/or pipelines. Careful use and monitoring of the triazine solution is needed to ensure smooth operation. Q2 Technologies has been manufacturing traditional triazine blends for decades and also offers expertise in developing unique formulas for special cases.

Check out this case study:

Non-Triazine Treatment

Even though triazine is a well-trusted solution, many companies have chosen non-triazine-based scavengers as alternatives for use in crude oil applications. One of the main characteristics of our non-triazine product, Pro3®, is a non-amine and non-glyoxal technology, making it safe for refineries and pipelines. If left unchecked, Amine salts that form from spent triazine can ultimately cause damage to the top stacks of a refinery when heated to >500 °F. Many refiners in the US Gulf Coast and overseas monitor amine content and require traders and midstream companies to use vetted non-triazine chemistries.

Producers and Midstream companies alike have found success with our non-triazine products:

- The quality of the oil is upgraded when H2S content is reduced.

- Safer environment for all personnel on-site.

- Infrastructure and equipment will last longer now that corrosion caused by H2S has been neutralized.

- Our non-triazine scavengers are not based on commodity-priced products, so our prices are protected and are less impacted by external factors such as freezes and industrial raw material shortages.

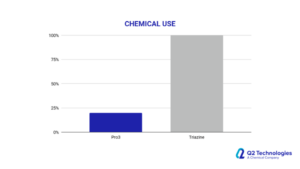

Our non-triazine H2S removal technology has proven to reduce chemical use up to 50-75% as compared to triazine. This definitely does not mean that triazine should always be replaced by non-triazine, rather, Q2 Technologies can assist you from a technical, engineering, and commercial viewpoint. Each application is different and needs to be carefully analyzed to determine the treatment product.

In conclusion, both triazine and non-triazine scavengers have their benefits and are the go-to alternatives for oil and gas treatment. But, one may be better than the other depending on the specific characteristics of the product that needs to be treated. If you’re looking for the right H2S scavenger solution for your company, feel free to contact us!

Sources:

https://www.sciencedirect.com/science/article/abs/pii/S1875510017304559

Complete H2S guide for Health and Safety

Hydrogen Sulfide (H2S) is a highly corrosive chemical found in Crude Oil, Natural Gas, Production Water, and Formation Water. The presence of H2S in Crude Oil and other volumes plays a significant health risk for those close to or exposed to this noxious substance. Because of its toxicity, if inhaled it can lead to numerous health problems and, in some cases, even death. Workers in the oil and gas Exploration, Production, Midstream, and Refining Industries may be exposed to this hazardous substance so they must follow a set of safety measures that are outlined below. Please consider the following as a starting point, always consult your company’s EH&S or manager for safety specific requirements.

Why is H2S so dangerous?

Health

- The health consequences of hydrogen sulfide depend on how much and how long the worker breathes it in. Exposures to concentrations of 100 ppm or more are harmful to human health. However, even at low doses, significant impacts are observed. The effects range from moderate, such as headaches or eye discomfort, to extremely dangerous, such as permanent loss of smell and taste to unconsciousness and death.

Damage

- In oil and gas applications, sour gas and sour crude (which contains H2S) can react with air and moisture to produce sulfuric acid, which can corrode metals. The durability and impact strength of facility equipment, particularly the inside surfaces of different components, are diminished, eventually resulting in premature failure.

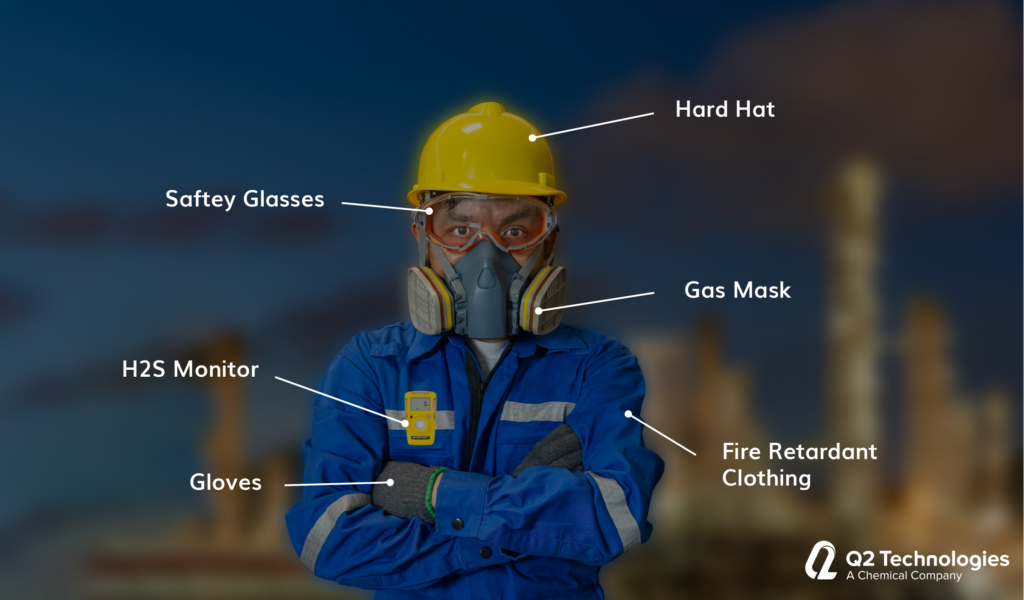

Safety Equipment

H2S Monitor

- Always make sure to carry an electronic meter that detects hydrogen sulfide gas. And clip the monitor near your face, on the lapel of your shirt for example. Always “bump test” by clicking the test button on the monitor prior to entering any job site to ensure the alarm on the monitor is loud – there may be large decibel producing equipment creating loud noises, your monitor should be louder so you can hear it.

- Do not rely on your sense of smell to detect the presence of hydrogen sulfide or to alert you of dangerous amounts. At low quantities in air, hydrogen sulfide has a “rotten egg” smell. However, after a while, you lose your capacity to detect the gas even if it is still present (olfactory fatigue). In large quantities, this loss of smell can occur extremely quickly, and the ability to detect the gas can be gone instantly (olfactory paralysis).

Protective personal equipment

- Wear respiratory and other personal protective equipment.

- Make sure you have been properly mask fitted to make sure you will be protected from hazardous vapors.

- If measures fail to lower H2S levels below the allowed exposure limit, respiratory protection must be used as well as additional personal protective equipment (PPE) such as eye protection and perhaps fire-resistant clothing.

Safety Measures

Imagine your hydrogen sulfide sensor has gone off, indicating the presence of H2S in your work environment. Now, what do you do?

1. Put On Your Gear:

Put on your gas mask if you have one handy and aren’t already wearing one. Pull your straps down firmly and breathe. While you evacuate the area, your mask will keep you safe.

The requirements for carrying a mask differ based on the setting, so if you don’t have one, don’t worry, just go on to the next stage.

2. Get Upwind:

- If you’re working in an area with the possibility of H2S release, there should be flags or windsocks on the work site to show you which direction the wind is blowing. Head in the opposite direction immediately. If you can’t see the windsock, toss some dirt or leaves into the air, or look at the trees.

- The wind can blow and concentrate the H2S into valleys or stands of trees, so the direction you go is essential. If you see a designated gathering area, or “muster site” downwind, go there.

- This is the easiest and most effective way to avoid H2S inhalation or poisoning.

- Lastly, if your work plan makes it difficult to evacuate an area, consider revising your work plan with your team before starting work in the first place.

H2S Removal

H2S Scavengers should be employed by crude oil companies to benefit from less fouling, corrosion, and property damage, significant reduction of health risks, and a potential increase in the value of production barrels.

In conclusion, anyone who has the possibility of being exposed to H2S must be ready with the recommended safety equipment and the know-how for whenever the H2S monitor goes off.

Always carry:

- H2S monitor

- Properly fitting PPE

If the monitor goes off, remember to:

- Put on your gear

- Get upwind

Q2 Technologies manufactures specialty H2S Scavenger Chemistry products that remove H2S from millions of barrels of oil every month. For more information, contact us!

Sources:

https://www.osha.gov/hydrogen-sulfide

https://www.draeger.com/library/content/h2s-ebook-enus.pdf

https://www.fldata.com/hydrogen-sulfide-oil-gas-industry

https://www.gdscorp.com/blog/hydrogen-sulfide/the-four-steps-to-take-in-a-hydrogen-sulfide-h2s-

Getting Ready for Hurricane Season

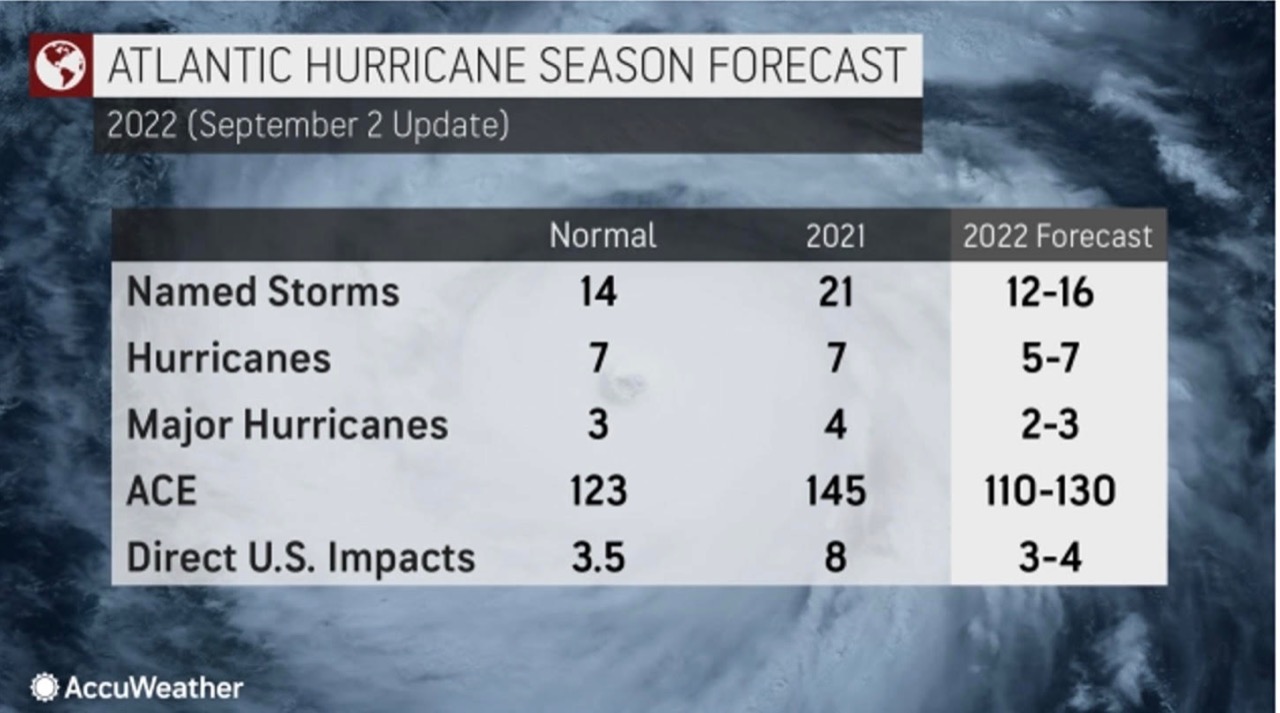

2021 was a rainy year, ranking as the third most active hurricane season in history as well as the third costliest, with a total of nearly $81 billion in damage. Hurricane Ida by itself, swept through Louisiana and much of Mississippi, forcing the shut down of refining operations and oil production in the Gulf of Mexico, and had a cost of over $75 billion in damages. Ida disrupted much of the chemical supply chain when it hit, leading to H2S scavenger raw material shortages.

[For 2022 ] An early outlook (…) forecasts an active North Atlantic hurricane season, which could affect oil and gas supply due to shut-in production at platforms in the U.S. Gulf of Mexico (HART Energy, 2022).

As meteorologists forecast an active hurricane season, producers, midstreamers, refiners, and chemical treatment companies must prepare for what could be a replay of last year’s heavy storms. For Q2 Technologies, it is essential for us to be ready; we know that these events can cause driver shortages, road/route closures, and production shut-ins at plants , which makes it extremely difficult to manufacture, deliver, and consequently treat oil and gas production. Despite hurricane season in full swing (the season actually starts June 1st lasting until November 30th), production at the wellhead does not stop, therefore Q2 Technologies is making the necessary arrangements to plan accordingly so our critical product is available during this uncertain time.

As a trusted chemical provider for our clients, we ensure that sufficient levels of our H2S removal products are securely stored close to our clients’ assets in anticipation of hurricane season.

We’ve taken the necessary steps to manufacture a sufficient amount of additional product and have coordinated ahead of time with our multiple trucking logistics partners to get product to location or storage. We stage at least 1 month worth of chemical inventory in West Texas and the Texas coast to ensure that any weather related supply disruptions will not jeopardize our delivery capability.

How do we manage to continue to deliver our product when a hurricane is imminent? This is actually a very simple answer: by being prepared, by manufacturing the product in advance, and before production is threatened. Having sufficient raw material from a diversified supplier pool at multiple manufacturing sites mitigates our production risk. Having multiple manufacturing sites allows us to deliver to multiple basins. We have been very strategic in our partnerships over the last 21 years, seeking partners with the highest integrity, and facilities with world-class blending that have easy access to major highways and thoroughfares.

Adaptability is also fundamental, depending on conditions, locations and our clients’ needs, we provide a wide range of different vessel formats, allowing our product to be ready for shipment in containers of all kinds of shapes and sizes: ISOs, Drums, and Totes.

Working at multiple manufacturing sites and being prepared with a fleet of trucks and carriers is critical. Multiple carriers are key for successfully delivering chemical loads. If, for any reason, one is delayed, another one may come to the rescue; partnering with different trucking companies has allowed us in previous years to successfully deliver our product and treat our clients’ crude oil and gas in a regular manner.

In conclusion, to seamlessly continue treatment in multiple basins while hurricane threats arise, we have implemented a “planning ahead” mindset:

- Multiple raw material providers

- Several manufacturing sites close to major highways and thoroughfares

- Diverse vessel sizes

- Multiple transportation services

- And stockpile field ready inventory

If you’re interested in our multiple H2S removal products, we’d be happy to have a chat with you! Contact us or give us a call +1 832-328-2200.

Sources

https://www.api.org/news-policy-and-issues/hurricane-information/hurricane-preparation

https://en.wikipedia.org/wiki/Hurricane_Ida

Cracking the Code on Treating H2S: Q2 Technologies’ Non-Triazine Scavengers Reducing Chemical Use Up to 75%

When it comes to treating Hydrogen Sulfide (H2S) in Crude Oil and liquid hydrocarbons, there are several types of triazine-based compounds that have historically been used. Unfortunately, if not closely monitored, the by-products of many of these chemistries can actually be more operationally detrimental and thus vastly more expensive, because overuse may cause corrosion and fouling in downstream systems. Fortunately, new technology has emerged! Q2 Technologies boasts a revolutionary new product that is in a class all by itself: Pro3® is an innovative non-triazine and non-amine H2S scavenger for Crude Oil and liquid hydrocarbon applications that is able to reduce chemical use up to 50-75% as compared to Glyoxal and MEA Triazine.

Less chemical

Pro3®’s active ingredient is chemically more effective and efficient at rendering H2S into non-reversible components than triazine could be, chemically speaking Pro3® is superior to triazine.

In a recent study, Pro3®, a non-triazine scavenger, was recommended to substitute a 40% MEA-triazine scavenger, resulting in an 80% cut on chemical consumption compared to triazine. This resulted in a reduction in deliveries and lowered the overall chemical spend. Read more about this case study here.

No Fouling and Corrosion

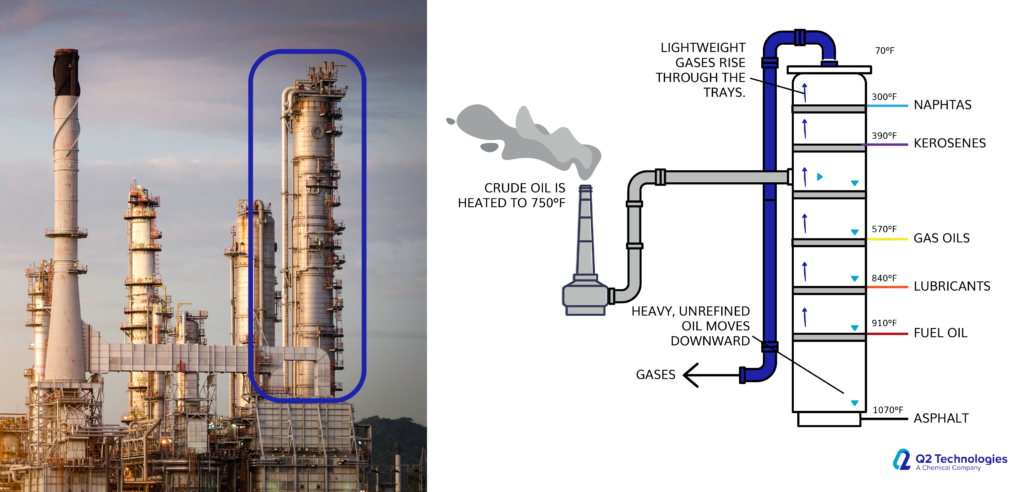

Q2 Technologies’ non-triazine product does not contain any amines or nitrogen compounds, making it 100% safe for refineries and pipelines. Amine salts from triazines can end up doing more damage to the top stacks of a refinery when heated to +500 °F as compared to the pinhole corrosion that H2S would cause if routed through the refinery untreated.

The distillation column is the backbone of any refinery and keeping the internals free of corrosion is critical. Refineries that manage asset integrity are constantly evaluating the inlet volume for amines and monitoring the physical nature of the columns.

Effect on supply chain

In the Spring of 2021 there was a significant winter storm event in Texas which had far reaching implications for the triazine market for much of the United States, and consequently Canada and parts of South America. The week-long deep freeze shuttered many chemical plants, and by the company’s estimates, nearly 90% of plants along the Gulf Coast that create the raw materials for triazine were shut down for months. This caused the near-commodity price of triazine to skyrocket: a classic under supply situation resulted in higher demand and the Oil & Gas producers and consumers were hindered by this for over a year. Q2 Technologies monitored this phenomenon closely. Since our Pro3® is a non-triazine based product, there were no supply chain issues and prices were not affected. Unfortunately, for those that depend heavily on triazine as a main scavenger, the threat of a shutdown could easily happen again, as some plants simply did not come back online in the summer of 2021, and those that were were repaired carry the additional operational burden to produce more and more triazine.

If scavenger costs and operational concerns are a priority, learn more about Pro3® and see how Q2 Technologies can lower your net chemical usage, protect infrastructure, and increase overall hydrocarbon production by rending H2S out. If you think your project can benefit from using Pro3® contact us today.

Removing Mercaptans While Keeping Costs in Line

There are several choices when it comes to treating mercaptans. Since mercaptans are highly complex branched sulfur-based hydrocarbon chains, treating them may require expensive solvents and scavengers, making it quite costly; not to mention that if treated with amine-based scavengers, dealing with fouling and corrosion is another expense to add. These factors were the impetus for developing ProM® for our clients, a mercaptan-treating product for meeting specs economically without having to deal with the effects of amine-based scavengers. By treating with ProM®, one can optimize the treatment process which can minimize the need for expensive blend stock or can even eliminate it. In this blog, we want to show you how our ProM® works and why it’s been a game changer for our clients.

What is ProM®?

ProM® is a mercaptan Scavenger. It has been specifically engineered to use non-triazine, non-amine based chemicals, which makes it safe to be used at refineries. This mercaptan removal technology is effective against Methyl, Ethyl, Isopropyl, Tert-Butyl, n-Propyl, sec-Butyl, Isobutyl, and n-Butyl mercaptans, just to name a few.

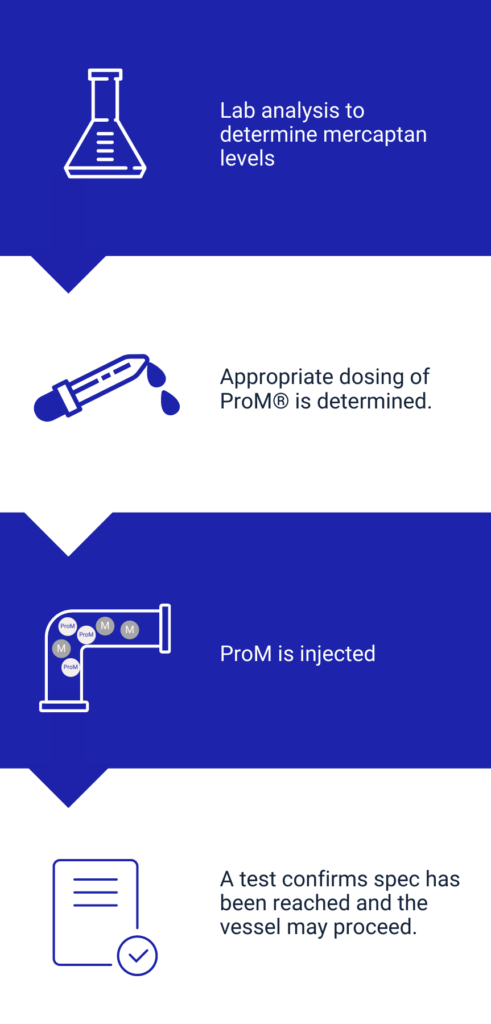

How does it work?

As we mentioned, unlike H2S, mercaptans are highly complex branched sulfur-based hydrocarbon chains, so they require lab analysis to determine treatment approach. Let’s say you are considering ProM® as an option, in order to know how much product your specific project needs, we would follow these steps:

- First, a lab analysis using method UOP163 and ASTM – D5623 is required to determine the mercaptan levels in ppm/w or the full speciation, respectively.

- Once analyzed, the appropriate dosing of ProM® chemical is determined.

- Then, we inject the product. Injecting on the suction side of the discharge pump allows for excellent contact and churn, ensuring the reaction is effective. The confluence of the chemical in Crude Oil ensures efficient mixture and treatment.

- Finally, a test confirms that quality spec has been reached and the vessel may proceed.

Mercaptan removal allows for better net back pricing on the barrel while meeting safety standards and protecting assets.

A real life example

A 50,000 bpd condensate splitter was facing fouling issues from MEA-Triazine. Also, they were using very high volumes of MEA-Triazine and still failed to reach crude oil mercaptan specification. As if this wasn’t enough, the terminal was required to blend down various types of crude oil from different storage tanks to achieve a mercaptan specification ranging from 2-5 ppm.

We’d seen that before, so we recommended ProM® to meet mercaptan specifications at the terminal to reduce the amount of blending required and reduce fouling and corrosion problems at neighboring condensate splitters. The results? ProM® chemistry allowed the customer to meet mercaptan specifications that MEA-Triazine was unable to reach. Here’s a link to this case study for your reference.

Lately we’ve been seeing increasing interest on this type of treatment because as we all know, everything keeps evolving, there’s no need to sacrifice one thing or the other anymore, by using ProM® you can:

- Meet specs

- Protect your assets

- Reduce or even eliminate the need for expensive blend stock

- Get better net back pricing on your barrel

- keep your costs in line

If you are looking for this type of solution, we’ll be happy to help, give us a call or send us an email.

Argus cites Q2 Technologies solutions as WTI quality causes concerns for midstream operators

On their News Article, Argus talks about the concern on quality of Midland-origin WTI cargoes loading in the Houston area and how Q2 Technologies has helped clean up these Permian Barrels.

“…Q2 Technologies is among the contractors working with producers and midstream operators to clean up Permian barrels, citing one case where it helped bring more than 50,000 b/d of Permian production to mercaptan levels of less than 75ppm, compared with pre-treatment levels of up to 600ppm” (Argus, 2022).

Take a look at the complete Article here

Contact us if you think we could also help you treat your crude.

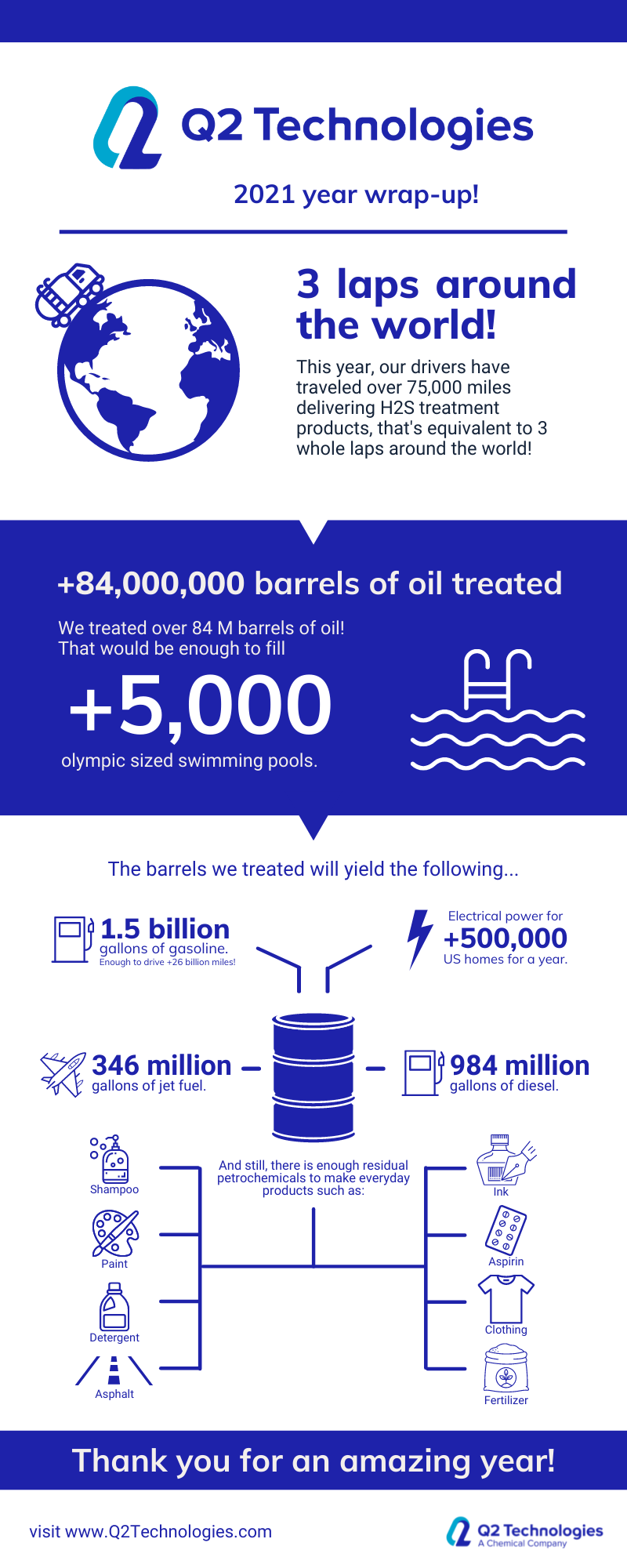

Q2 Technologies Wraps-up the Year with +84 million Barrels of Oil Treated

Q2 Technologies by the numbers!

Check out our “by the numbers” wrap-up of the year – it has been a tremendous 2021! Our focus continues to be adding value to your barrel. Barrels afflicted with H2S or mercaptans can significantly degrade the netback price, by treating with our ProSeries products, one will have a more merchantable, safer, more valuable barrel.

As seen on the news (Yahoo!Finance, MarketWatch, PR Newswire and many more) here is our 2021 recap:

Q2 currently treats in 5 different time zones at the wellhead for Producers, in the pipeline and terminals for Midstreamers, and at dock tanks, lightered vessels at port, and beyond into VLCCs.

Q2 Technologies Expands Capabilities with New Field Operations Manager

Q2 Technologies in the News

Q2 Technologies’ recent announcement is making the rounds as seen on Cison PR Newswire, Market Watch, Seeking Alpha, Yahoo! Finance, and many local news outlets.

HOUSTON and MIDLAND, Texas, Nov. 16, 2021

Q2 Technologies, a specialized chemical company, adds Ever Chavez as Manager of Field Operations to their growing team. Hugo Lozano Jr, VP and General Manager of Q2 Technologies said, “Ever brings tremendous experience and leadership in technical and operational chemical blending from his background at Tech Management and Baker Hughes. We are excited to have Ever on board to develop our growing chemical treatment business in the Permian and beyond.”

Ever’s Background

Chavez brings over ten years of chemical process and control engineering experience in the Upstream and Midstream business. His responsibilities will be to grow the established chemical treatment and blending operation Q2 Technologies has established in the Permian Basin, service Q2’s growing customer base, and continue to build the specialized product offerings Q2 provides to other multiple locations.Prior to joining Q2 Technologies, Chavez was with Tech Management. His increasing responsibilities allowed him to focus on overseeing QA/QC testing of product blends. This way, he ensured each product met appropriate standards and measures. Additionally, he has valuable experience in water analysis, chemical compatibility testing, friction flow loop analysis, emulsion testing, and other hydrocarbons specific testing methods. Further, Chavez spent over four years with Baker Hughes in Midland, Texas in account management where he focused on the technical aspects of growing, evaluating, and processing large-scale customer orders. “This is such an exciting time at Q2 Technologies, I’m excited to take on the responsibility to build the established footprint the company has built and take it to the next level. The proprietary and triazine/amine-based suite of products Q2 provides is a significant advantage and I look forward to ensuring that these products are manufactured, delivered, and administered to the highest qualities for our customers,” said Chavez, who holds a B.A. in Industrial Engineering and MBA from the University of Texas at El Paso.

Continuously working to create value for customers

Chavez’s business development acumen and insight will be an additional resource for Q2 Technologies. “Ever has a great blend of technical, commercial, and economic experience in the Oil & Gas industry specially as it pertains to the chemical and treatment aspects,” added Philip Weigand, Vice President of Business Development for Q2 Technologies, “and I am thrilled to have him on the team to continue what we have started: creating value for our customers by treating H2S and mercaptans.”

About Q2 Technologies, LLC

Q2 Technologies specializes in increasing the value of crude oil barrels by offering several solutions: Pro3® line of non-triazine H2S scavengers and ProM® line of non-triazine mercaptan scavengers for crude oil applications. The Pro3® /ProM® technologies currently treat over 6 million barrels of crude oil and condensate each month at major pipelines and terminals in the US. For more information, contact Philip Weigand at 323753@email4pr.com or +1 (832) 328-2200.Q2 Technologies has been in business for over 20 years. The company is a spin-off of Quaker Chemical (NYSE: KWR) and developed the MEA-Triazine scavengers used world-wide today in the late 1980’s. Q2 Technologies is an expert in H2S and mercaptan removal solutions. Q2 Technologies has H2S and mercaptan removal experience in the oil & gas, pulp & paper, wastewater, and landfill gas industries. By combining its experience and research and development within these industries, Q2 Technologies offers superior engineering, application, and chemical solutions.

Treating Trucked Sour Crude

Unique Treatment Solutions

Barrels that have moderate to high levels of H2S are typically challenged economically from the start. First, from a safety standpoint – more oversight, training, CAPEX & OPEX, and effort goes into protecting the people and assets involved. Next, the untreated barrel will likely get rejected commercially and will not move via pipeline, which leaves trucking that sour barrel to market as the only alternative. Unfortunately, as a double whammy, that trucked sour barrel typically goes to a market that stacks yet another financial hardship on its value: a dreaded sour oil deduct on the netback price. The value erosion on that barrel can be a significant drain on the Producer, and in some plays the whittling away on the sour barrel can be borderline uneconomic. Ugh!

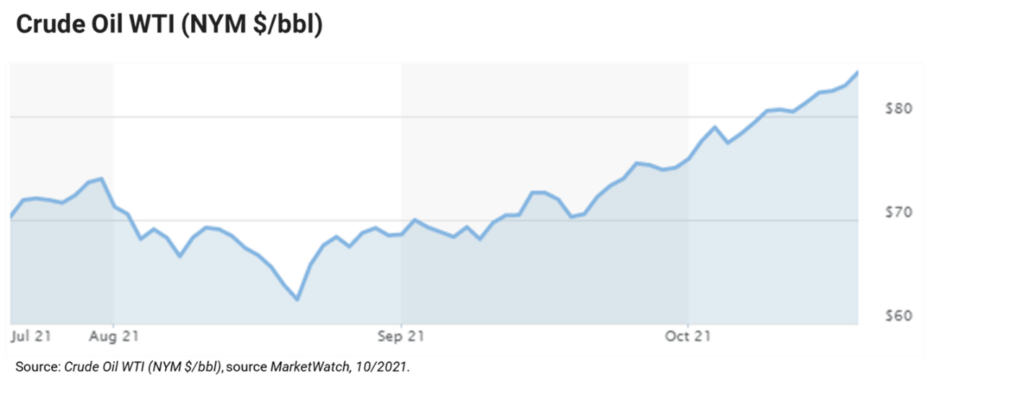

With higher overall WTI per barrel in Q4 2021, more production is likely on the way to realize the price bump. In fact, production in the Permian is heading back to pre-pandemic levels increasing output to an average of 4.826mmbls/d in October, according to a recent ClusterX article citing a U.S. government report. Which is just shy of the record set in March 2020 at 4.913mmbbls/d right before COVID-19 fundamentally disrupted global demand and sent supply reeling. Although the industry has done a good job in the previous years building out the gathering and long-haul pipeline systems, trucking fills in the gaps. Although difficult to pin down an exact number, trucking in the Permian has always filled the takeaway gap and according to several historical reports, several thousand truck haulers operator daily – which means potentially a quarter million+ barrels are being hauled in the Permian at any given time. And in this case for sour barrels, Producers and Midstreamers rely heavily on this critical delivery component. It can be challenging to commit capital to build pipelines to inherently less valued barrels due to the presence of their sulfur content, and so, many sour barrels are stranded in the field to be delivered only by truck.

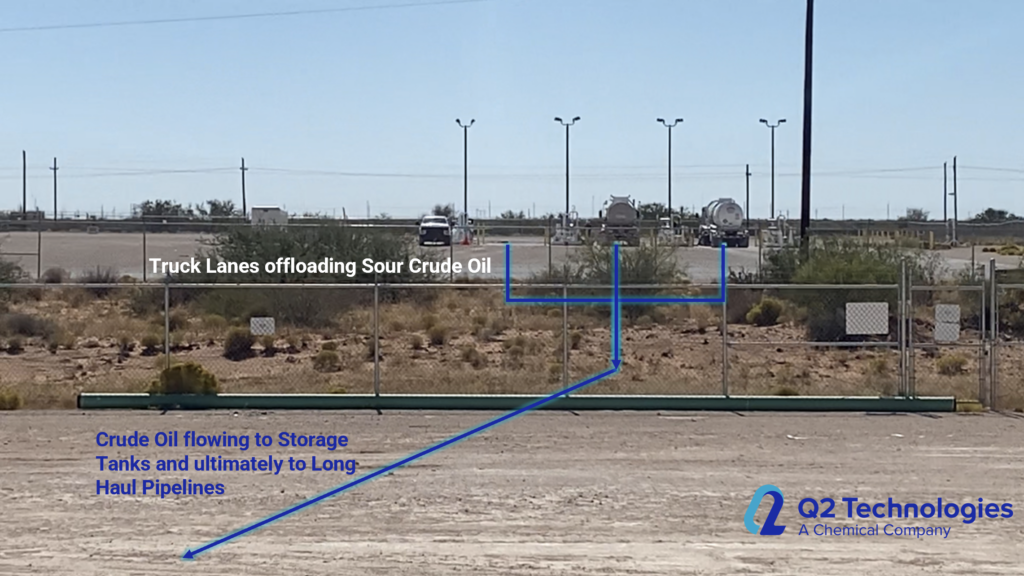

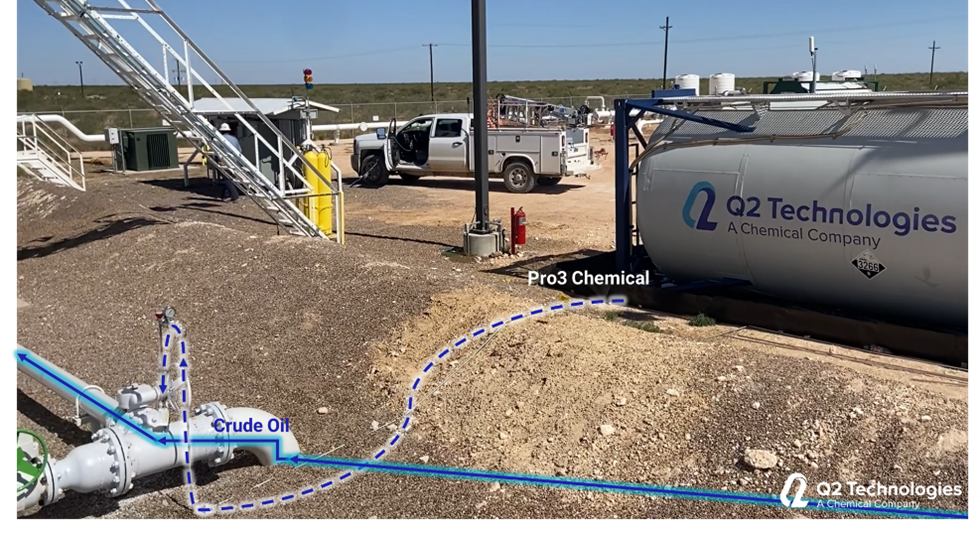

Fortunately, there are treatment solutions available, and economic ones a that! Q2 Technologies recently implemented a system for a leading Midstream company to accept H2S barrels to treat automatically at an existing multi truck lane LACT station. This novel approach makes economic sense to all parties involved; here’s how it works:

Once the oil hauler, who is transporting a sour barrel, begins pumping volume at the facility, the lease automatic custody transfer (LACT) sends a signal to the Q2 pumps to being dosing. The crude oil is then treated as it is transferred in the tanks. Once treated, the barrel meets H2S specifications and can be sold into a sweet market. This setup is capable of treating all lanes simultaneously several thousand barrels per day at H2S levels in tens of thousands of ppm.

Net benefit to all:

Producers are able to produce their sour barrel and deliver it to a facility that is tied into one of the premier markets in the Permian, in order to fetch the highest netback prices available. Oil haulers are staying busy moving product to market. The Midstream company did not have to reject that sour barrel, thus increasing throughput and generating additional revenue. A win-win-win!

The comingled lines are routed to a single point where treatment occurs. Oil Haulers transport approximately 190bbls per load, and this facility receives several dozen loads per day of H2S ladened crude oil.

As the crude oil flows towards the tank battery, Q2’s Pro3 product is injected, thus ensuring that treated volume enters the tank battery array. This configuration allows for all truck lanes to offload and be treated simultaneously without pressure or flow upsets.

Sources:

https://content.clusterx.com/articles/1018-oil-production-permian-shale-nearing-pre-pandemic-levels

https://www.eia.gov/dnav/pet/pet_pnp_caprec_dcu_r30_a.htm

https://www.marketwatch.com/investing/future/crude%20oil%20-%20electronic

Q2 Technologies company data, 2001-2021.