Quality Chemicals Matter

Quality control is the basis for our business. Delivering high-quality products is fundamental to our clients. Providing consistent, high-quality products time and time again leads to long-term and trusted partnerships.

Therefore, keeping a close watch and testing our batches ensures our manufacturing processes are not deviating and we deliver the highest quality possible.

In much the same way, when out in the field, we are often asked to check unknown products. This arises at the request of the client if their existing product is not effective or worse, causing production hindrance. This is performed as a troubleshooting effort for our clients and is the starting point in discovering a workable solution.

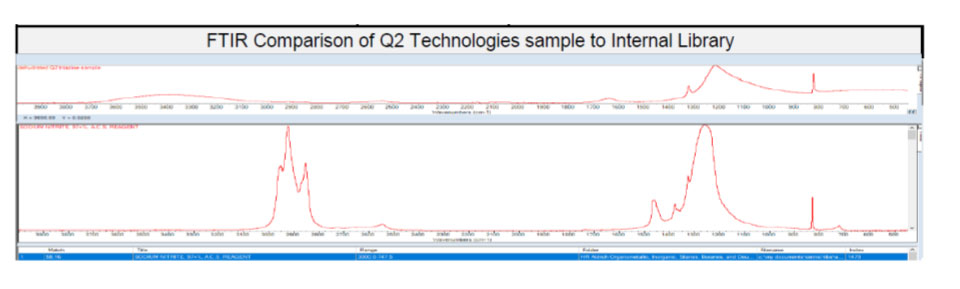

So how do we ensure in the lab that our manufactured products are meeting our exacting standards or how we determine what an unknown field substance may contain? One of the many advanced ways we detect the presence of different ratios of chemistries is by utilizing a Fourier-transform infrared spectroscopy (FTIR) unit.

Maintaining the highest quality of our chemical products is fundamental to how Q2 Technologies ensures we maintain our trusted partnership status for leading Oil & Gas producers, midstreamers, refiners, biogas, and wastewater operators. We rely on proven technologies not only for our chemical products, but how we implement them in our growing range of industries.

Not Just in the Name

For over 20 years, Q2 Technologies has been at the forefront of chemical development and implementation in Oil & Gas, and as such, ‘technologies’ is a core concept we embrace from early stage chemical development, to the logistics of manufacturing, to final implementation for the end-user. Our clients know that we scrutinize all aspects of our process and it shows in the results of having consistent products at or near the clients’ locations every day of the year. Check out our latest inventory initiative announcement here.

One of the more advanced techniques we utilize to ensure our unique products are manufactured to our tight specifications and standards is the use of infrared (IR) spectroscopy. IR spectroscopy, specifically Fourier transform infrared (FTIR) spectroscopy, is a widely popular analysis technique used today. FTIR is used across many industries as the process is quite adaptable to suit many scenarios. Considering that it has use cases for all types of matter: solid, liquid, and gaseous analytes.

How it works

The study of infrared light dates back to the astronomer William Herschel in the early 19th century. Herschel used a prism to refract light from the sun and noticed the temperature increase when focused beyond the red portion of the spectrum. Although the term infrared was not used until the late 19th century, beyond the visible red light was surely a curiosity to him. Since then, the study of the interaction of IR light with matter has expanded greatly. In the ongoing studies with a FTIR device, a light source shines on a substance and the resulting wavenumber or unique IR signature is observed on a detection plate. The study of chemical bonds has proven that molecules are not held together in static fashion, rather they vibrate at the molecular level leading to concepts of symmetrical and asymmetrical stretching, wagging, scissoring, rocking, just to name a few, and when IR light attempts to pass through certain molecules that are vibrating at different frequencies, we can determine with high confidence that a particular molecule is present. The process yields a detection graph that will have a series of unique identifiers that would confidently point to different chemicals present.

The FTIR test would be akin to a baker identifying all of the ingredients of a cake, to replicate the recipe, one would need the measurements of each ingredient. That is where we pause in our evaluation of unknown substances, chiefly we do not need to recreate a substance and secondarily, this is where the science and artform deviate, beyond the FTIR test, one is making gross assumptions. However for our purposes, the resulting identification of the presence of certain elements is quite sufficient, with this information we are able to make inferred rational judgements on the nature of a product. Again this works well for our quality control best practices, for example if a significant presence of an out of place molecule shows, we may with statistical evaluation conclude that the sample has been contaminated and would need to be reconfigured. To be fair, significant deviations are taken into account, as well as a deep understanding of how our product would chemically react to the rogue molecules.

Putting it into Practice

As part of our professional service offerings of supplying chemical products to our clients’ different facilities, we take a concerted effort to ensure that the products are delivered on time to location and are administered appropriately. Word can travel fast in the oil patch and this can lead to potential clients requesting us to troubleshoot why their chemical products are not as effective or at worse causing production curtailment, in short, they are seeking to know what is causing the issue. We start by reviewing the SDS and comparing that to what the FTIR analysis provides. In some cases, products are diluted or manufactured with other chemicals, rendering them less effective. Oftentimes, a solution for H2S or mercaptan treatment from our ProSeries® suite of products is a good fit and we are able to quickly scope out a workable application.

If you would like to learn more about how we use FTIR analysis in the lab or how it may apply to your asset in the field for hydrocarbons afflicted with H2S or mercaptans, we would be happy to discuss with you your situation to find solutions. Contact us today!

Sources:

https://www.advancedmicroanalytical.com/AMAServices.aspx?mode=tech&id=15

FTIR Image Source:

https://calce.umd.edu/fourier-transform-infrared-spectroscopy

Related Articles

Avoiding Costly Mistakes – The Importance of Sampling in H2S Testing

October 06, 2017

H2S Test Methods

March 14, 2019

H2S Removal Technologies in Crude Oil

April 18, 2019