Scalable from wellhead to full scale gathering systems.

Pro3® Nano

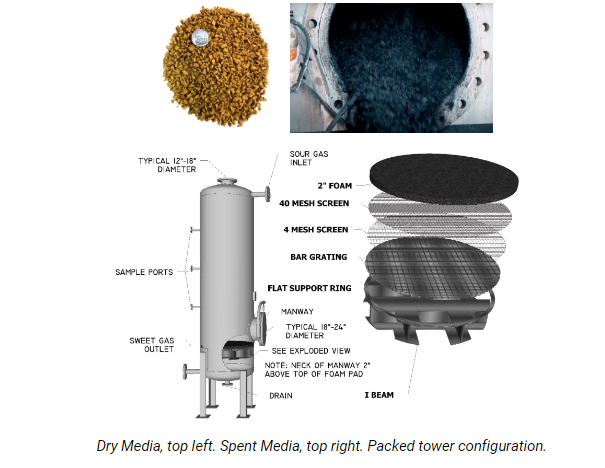

After years of commercial success in every major oil and natural gas basin in the US, Q2 Technologies is please to offer this game changing non-triazine H2S scavenger solution. The Pro3® Nano dry media is packed in specially designed towers that absorbs and chemically reacts to the inlet sour natural gas, converting sour gas into sweet gas that meets commercial pipeline specifications. Read about Pro3® Nano’s chemistry and its first commercial application here.

Compare Pro3® Nano against Triazine.

Benefits throughout

- No scale or blocking buildup as compared to over treated triazine situations.

- Hands free: No pump skid required, gas simply flows through the Pro3 Nano media in the tower.

- Capable of handling massive swings in volume and spikes in H2S.

- Non-hazardous elemental sulfur byproduct.

Digitize your Field

- Real time H2S readings, injection rates & tank levels

- SCADA, GPS, cell connections

- Web based app for remote monitoring automation, remote pump adjust via app

- The contactor tower is filled with Pro3® Nano, flow rate of Natural gas, H2S levels, and pressures are all considered for design parameters.

- Sour gas is routed through the bottom, produces non-hazardous iron and sulfur-based slurry. Sweetened gas makes it way out the top of the unit into the sales line.

- When compared to triazine in head-to-head comparisons, Pro3® Nano media can last twice as long, which lowers overall OPEX and down time.

FAQs

– Pro3® Nano lowers operational expenses (OPEX) by lasting twice as long as triazine, reducing the frequency of media replacement.

– It eliminates scale buildup and blockages caused by over-treatment with triazine, minimizing maintenance costs.

– The solution does not require a pump skid, reducing equipment and operational complexity. – It enables the treatment of more sour gas, increasing production and margins.

Pro3® Nano produces a non-hazardous elemental sulfur byproduct in the form of an iron and sulfur-based slurry.

– Real-time H2S readings, injection rates, and tank levels.

– SCADA, GPS, and cellular connections for remote monitoring.

– A web-based app for automation and remote pump adjustments.

– It handles large volume fluctuations and H2S spikes without performance loss.

– Eliminates the need for frequent site monitoring, reducing manual intervention.

– Prevents scale buildup and blockages, improving system reliability.

– Lasts up to 2.5 times longer than triazine, reducing downtime and treatment frequency.

Related Case Studies

Natural Gas - Pro3® Nano

Dry catalyst and reactor system for natural gas applications, Consistently meets pipeline quality specifications.

- Pro3® Nano replaced Triazine reducing the cost of treatment and

allowed treatment of more sour gas which could not be sweetened with Triazine, thereby increasing production and margins.