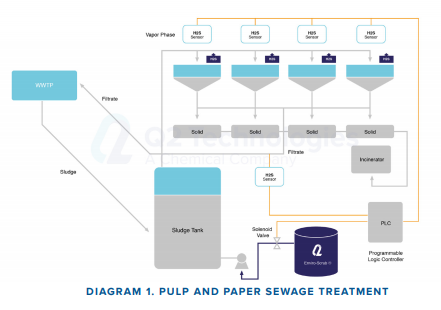

PULP AND PAPER H₂S TREATMENT

A pulp and paper mill was processing 500 gpm (720,000 gallons per day) of sludge, with 3% solids, through four presses. The dewatered solids were being burned, and the filtrate was being returned to the waste-water treatment system.

H2S in sludge was liberated at the presses. The H2S levels typically ran between 40-100 ppm. However, there were some spikes in H2S levels reaching about 750 ppm. These H2S surges were due to changes in throughput volume and feed composition.