Understanding their Role in H2S Removal

A Quick Primer: What Is a Hemiformal?

HCHO + ROH ⇌ RO–CH₂–OH

The resulting compound, RO–CH₂–OH, is known as a hemiformal. Structurally, it is characterized by a carbon atom bonded to both a hydroxyl group (–OH) and an alkoxy group (–OR), making it a hemiacetal. In this case, the aldehyde is formaldehyde. A common example is methoxymethanol (CH₃OCH₂OH).

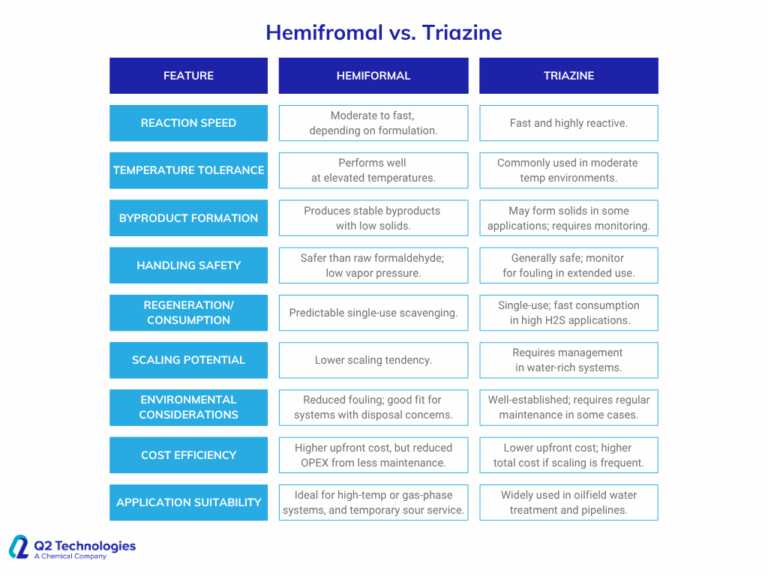

Unlike pure formaldehyde or triazine-based scavengers, hemiformals offer a unique balance of reactivity, stability, and handling safety. Their molecular structure makes them especially effective at reacting with nucleophilic species, such as hydrogen sulfide (H₂S), making them suitable for various industrial applications.

What is a hemiformal used for in H2S removal?

A hemiformal is used as safer, controlled-release formaldehyde sources in hydrogen sulfide scavenging. It’sideal for gas sweetening, water treatment, and temporary sour service.

Historical Context and Development

The use of formaldehyde derivatives in gas treatment dates back several decades. Early scavengers relied heavily on unmodified formaldehyde, which raised safety and regulatory concerns due to volatility and toxicity. This led to the development of more stable alternatives—hemiformal being one of them. Its ability to release formaldehyde in situ, under controlled conditions, offered a safer and more targeted approach for H2S mitigation.

Over time, hemiformal gained popularity in applications where triazine scavengers were less effective, such as high-temperature systems or operations requiring reduced scaling tendencies.

How a Hemiformal works as Scavenger

When introduced into a stream afflicted with H2S, the hemiformal decomposes to release formaldehyde, which then reacts with hydrogen sulfide to form stable, non-volatile byproducts such as thiomethylene glycol. The reaction is typically fast and efficient, particularly in aqueous or mixed-phase environments. Unlike some traditional scavengers, hemiformal can maintain activity across a broad pH range and is less likely to generate problematic solids. When considering if hemiformal is the right product, certain operating conditions are reviewed, such as pH and temperature.

Key Benefits:

- Controlled formaldehyde release

- Lower vapor pressure and improved safety profile

Broad applicability across liquid and gas-phase systems - Reduced scaling in sour water stripping and other high-temp operations

- Hemiformal can make the scavenger safe for transport as it is a very stable compound

Applications Across the Industry

- Gas sweetening systems

- Produced water treatment

Broad applicability across liquid and gas-phase systems - Crude oil storage and transport

- Sour water stripper overheads

- Temporary H2S mitigation during maintenance or turnaround

Its adaptability makes it especially useful in operations where system conditions fluctuate or where traditional triazine-based products may underperform.

Considerations and Limitations

While hemiformal offers many advantages, it is not a one-size-fits-all solution. The rate of formaldehyde release can vary depending on formulation and environmental conditions. Additionally, while safer than raw formaldehyde, hemiformal must still be handled with care and appropriate PPE.

For optimal results, formulation expertise and application-specific customization are key—something we at Q2 Technologies excel at delivering.

The Q2 Advantage

Looking to explore whether hemiformal is the right fit for your operation?

Contact us to learn more about our tailored H2S solutions.