Friday, November 1, 2024

Landfill Biogas Industry Snapshot

Discover how the U.S. biogas industry is turning waste into renewable energy and see the scale of this impact with…

Q2 Technologies Team

Experts in H2S Scavenging Solutions

With decades of combined experience, the Q2 Technologies team specializes in innovative hydrogen sulfide (H2S) scavenging solutions for the oil and gas, wastewater treatment, and industrial sectors.

What is Biogas?

Landfill biogas is created when organic materials, like food scraps, common household trash, paper waste products, even baby diapers, decompose in landfills. As they break down, they produce methane, a potent greenhouse gas. But instead of letting this methane escape, biogas systems capture and convert it into renewable energy.

Imagine each landfill as a source of methane gas. As waste breaks down, methane is released. If left unchecked, this gas escapes into the atmosphere, contributing to greenhouse gas emissions. However, biogas systems capture this methane and convert it into energy.

In recent years, the U.S. has significantly increased its investment in biogas systems to prevent methane from escaping into the atmosphere. In 2023 alone, $1.8 billion was invested in nearly 100 new biogas projects, bringing the total to over 566 landfill gas (LFG) projects nationwide. This growing infrastructure helps capture and convert methane into renewable energy, making a major contribution to reducing emissions. Now, let’s take a look at some numbers to understand the scale of this effort.

What is Methane Production in the U.S.?

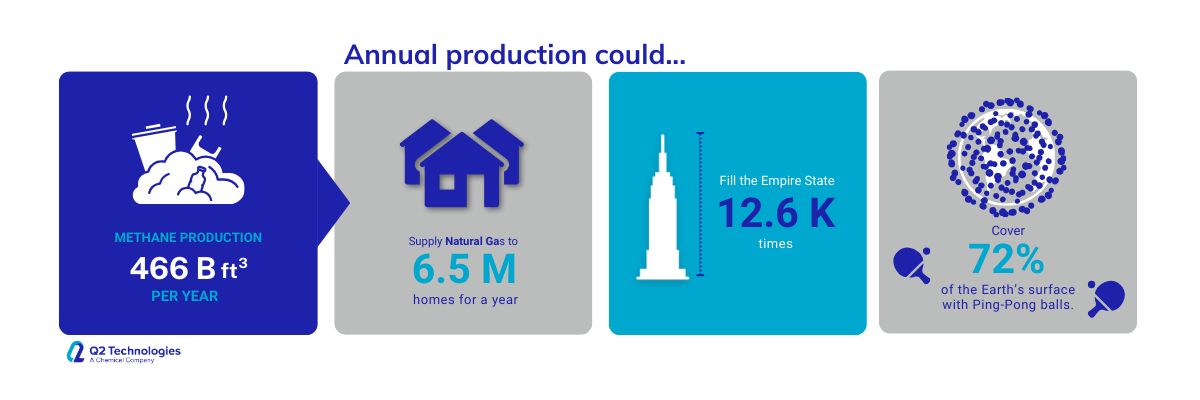

The U.S. produces 466 billion cubic feet of methane annually from landfills. The U.S. Energy Information Administration (EIA) states that the average U.S. household uses about 196 cubic feet of natural gas per day for heating, cooking, and appliances. So, the methane produced by U.S. landfills annually could supply natural gas to approximately 6.5 million homes for a year.

466 billion cubic feet is an unbelievably large figure, so here are some comparable visuals. The methane produced annually could…

- Fill the Empire State Building about 12,600 times!

- Cover approximately 72% of the Earth’s surface with a single layer of ping-pong balls!

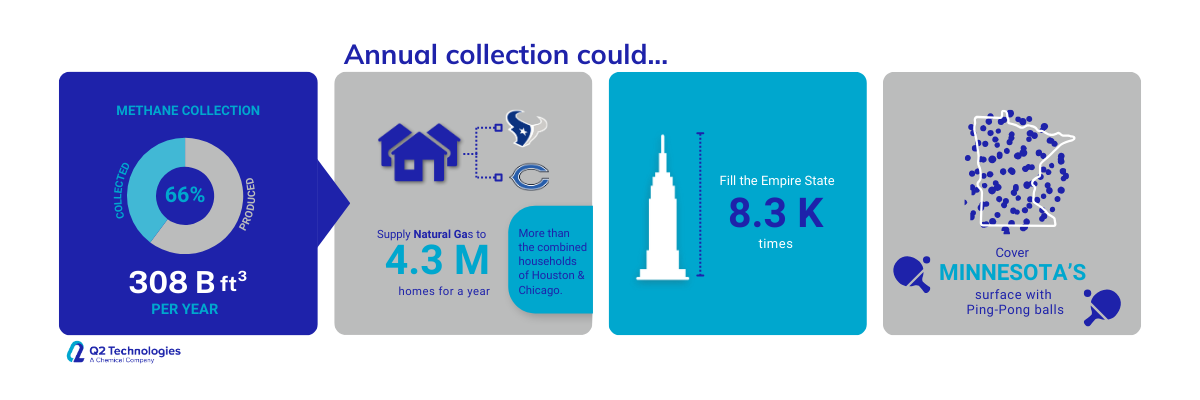

This figure represents if 100% of the methane in the U.S. is captured, today, only about 66% of the production is collected, amounting to ~307.6 billion cubic feet annually. That’s enough to power about 4.3 million homes for a year, which is more than the combined number of households in cities like Houston and Chicago.

The methane collected could…

- Fill the Empire State Building about 8,300 times.

- Fill 4,785 Olympic-sized swimming pools with ping pong balls—each packed with methane gas. That’s how much space you’d need to hold 307.6 billion cubic feet of methane!

The Biogas Production Process

Source: https://d3.harvard.edu/platform-rctom/submission/waste-ing-our-planet-away/

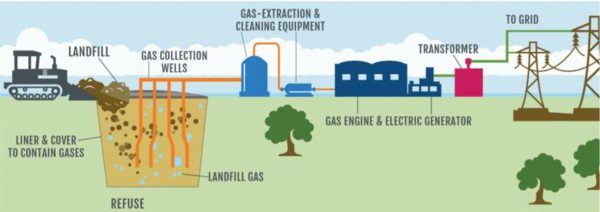

The process of producing biogas involves anaerobic digestion, a natural process that occurs in the absence of oxygen. Here’s a breakdown of the steps:

- Waste Collection: Organic waste from landfills is collected and transported to biogas facilities.

- Anaerobic Digestion: The waste can be placed in sealed tanks or digesters, or in open pit landfills, dozens of feet of waste effectively seal the refuse in a depleted oxygen zone where microorganisms break down the organic matter. The key is the absence of oxygen.

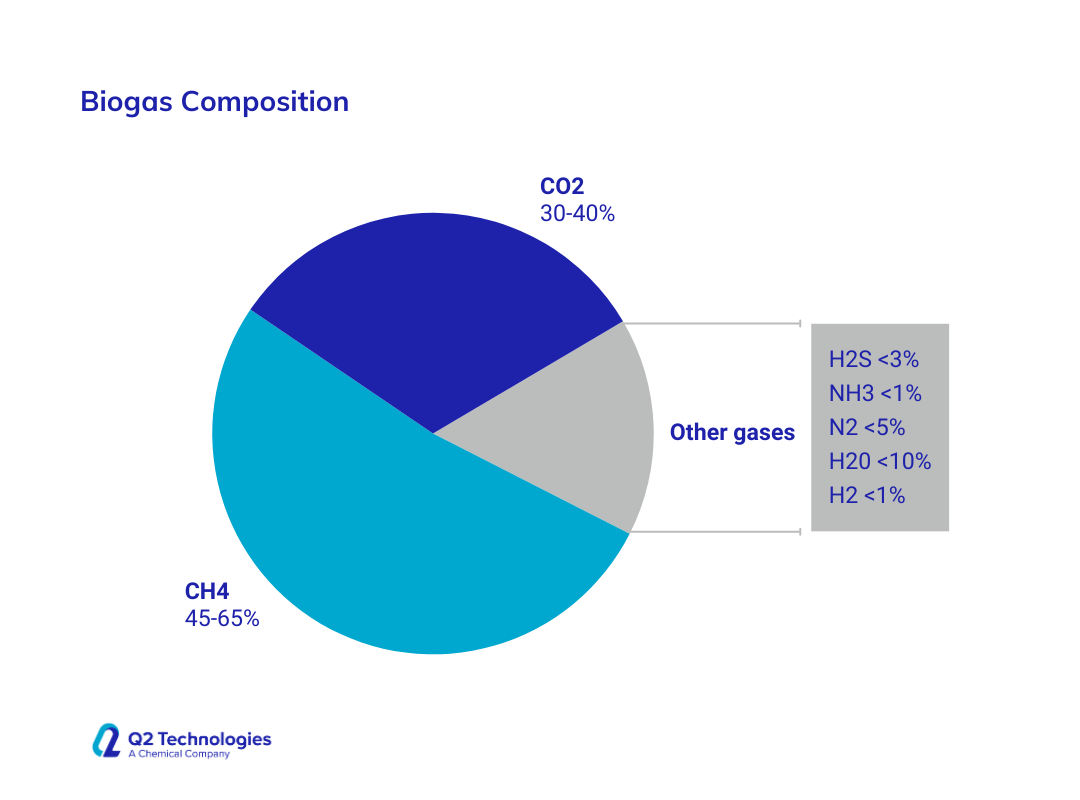

- Biogas Formation: During this process, methane and carbon dioxide are produced.

- Gas Processing: The biogas is cleaned and processed to remove impurities, such as carbon dioxide and hydrogen sulfide.

- Energy Generation: The purified biogas can then be used to generate electricity, heat, or transportation fuels.

Biogas Treatment and Purification

Once landfill biogas is captured, it goes through several stages of treatment to make it suitable for energy production. The primary goal is to remove impurities such as hydrogen sulfide (H2S), moisture, and carbon dioxide (CO2):

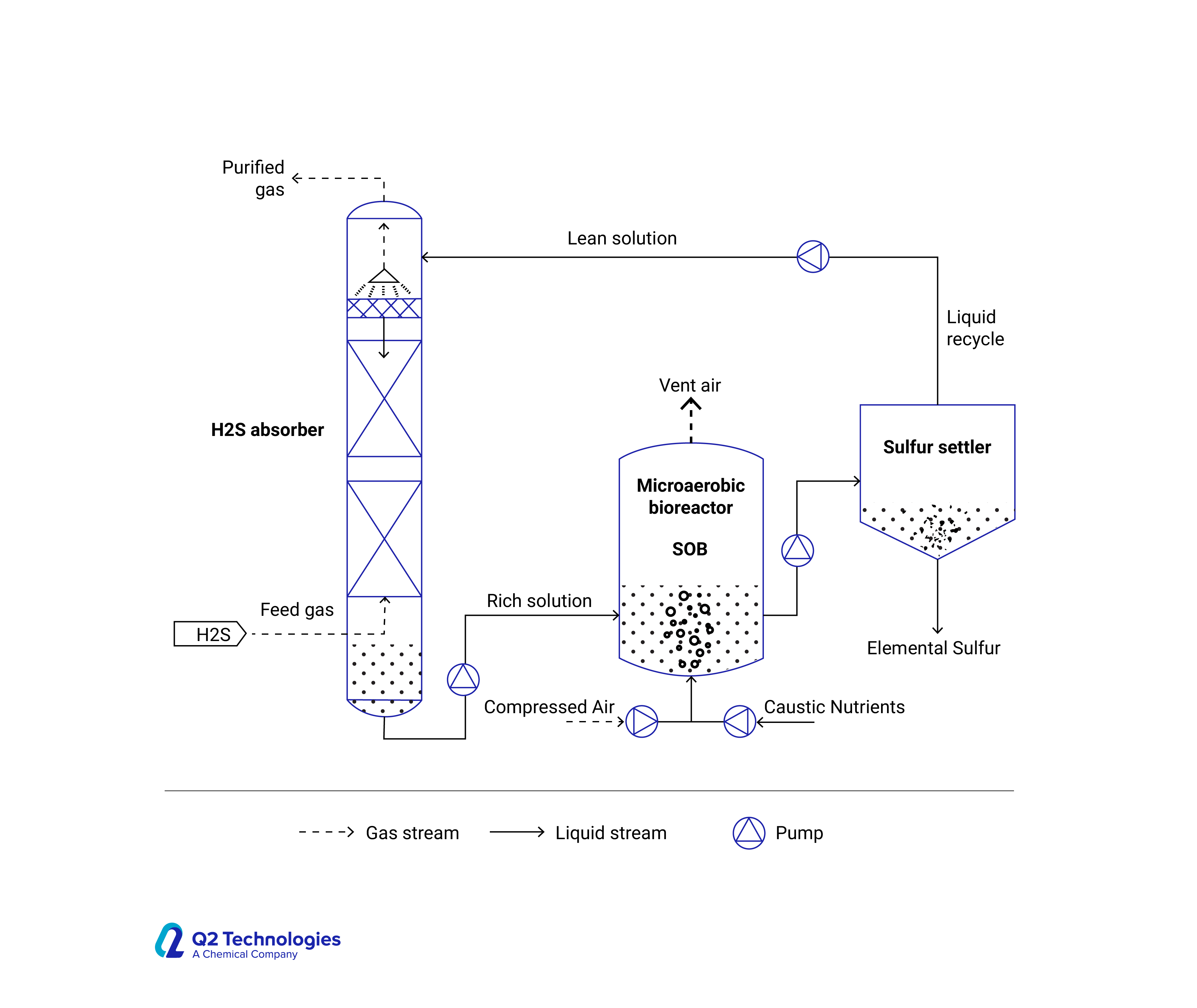

Desulfurization

One of the most important steps in biogas treatment is the removal of hydrogen sulfide (H2S), a harmful and corrosive gas. H2S removal is achieved through various methods such as chemical scrubbing (like Enviro-scrub), biological filters, or activated carbon.

Moisture Removal

Water vapor is typically removed by condensation or absorption methods to ensure the biogas is dry before being used for electricity generation or upgraded into renewable natural gas (RNG).

CO2 Removal

To increase the energy content of the biogas, carbon dioxide is separated from methane. This is usually done using pressure swing adsorption (PSA), membrane separation, or amines.

Upgrading to Renewable Natural Gas (RNG)

Once purified, biogas can be upgraded to pipeline-quality RNG, which can be injected into natural gas grids, used as a transportation fuel, or compressed for vehicle use.

What is the Future of Biogas in Emissions Reduction?

Even though we’re making significant strides in capturing and treating landfill methane, there’s still work ahead. Today, the U.S. collects 66% of the methane produced, but with ongoing investment in biogas systems, we can aim for 100% collection and treatment. By improving treatment, such as H2S removal and CO2 separation, we can further reduce emissions and generate cleaner energy. If you’re involved in a landfill project and need expert H2S scavenger solutions, feel free to contact us.

Bonus: 3 Common Questions About Landfill Biogas

1. What are the main benefits of landfill biogas systems?

Landfill biogas systems capture methane emissions from decomposing waste, preventing this potent greenhouse gas from entering the atmosphere. The captured gas is then converted into renewable energy, helping to reduce emissions, support sustainable energy goals, and provide a reliable source of power for homes and industries.

2. How does landfill biogas contribute to sustainable energy?

Landfill biogas offers a renewable energy source by turning waste into a resource. Methane captured from landfills is processed and used to generate electricity, heat, or transportation fuels, reducing dependency on fossil fuels. This transformation not only mitigates environmental harm but also aligns with sustainable energy initiatives by repurposing waste into clean energy.

3. Is H2S present in biogas?

Yes, hydrogen sulfide (H2S) is a common impurity in biogas. It is corrosive and harmful, so it must be removed during the treatment process. Advanced desulfurization methods, such as chemical scrubbing, biological filters, or activated carbon, ensure the biogas is safe and efficient for energy production.

At Q2 Technologies, we support cleaner energy solutions by offering advanced H2S scavenger technologies that optimize landfill biogas treatment systems

Sources

Analysis for Anaerobic Digestion

https://www.biocycle.net/quantifying-landfill-biogas-production-potential-in-the-u-s/

https://www.eia.gov/dnav/ng/hist/ngm_epg0_fgw_nus_mmcfdm.htm

Related Articles

HOW CAN WE HELP?

Have a question? Need a quote? Our technical staff is here to help you identify the right solution for your project requirements.