Join us and 400 others at this very special industry conference at the Hilton Americas in Houston from January 22nd. through the 24th. Q2 Technologies is one of the proud sponsors of this unique opportunity to gather insight on our fast-moving oil industry for 2019.

Hear industry speakers share their perspective on the global crude market, including:

- The impact of increasing US crude exports, Marpol 2020 regulations and global demand growth

- Future infrastructure and pipeline developments from the Permian and investment in US Gulf coast export infrastructure

- Geopolitical uncertainty and the impact on global trade flows

- Hot spots – developments in Venezuela, Mexico, Iran and more

- Canadian crude market and pipeline constraints

- Outlook on global crude demand in the short and long-term

- OPEC developments and counterbalancing the market

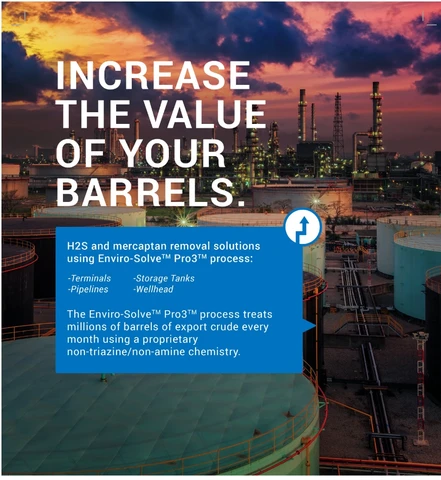

What is Non-Triazine Treatment?

Even though triazine is a well-trusted solution, many companies have chosen non-triazine-based scavengers as alternatives for use in crude oil applications. One of the main characteristics of our non-triazine product, Pro3®, is a non-amine and non-glyoxal technology, making it safe for refineries and pipelines. If left unchecked, Amine salts that form from spent triazine can ultimately cause damage to the top stacks of a refinery when heated to >500 °F. Many refiners in the US Gulf Coast and overseas monitor amine content and require traders and midstream companies to use vetted non-triazine chemistries.

Advantages of Non-Triazine H2S Scavengers

Producers and Midstream companies alike have found success with our non-triazine products:

- The quality of the oil is upgraded when H2S content is reduced.

- Safer environment for all personnel on-site.

- Infrastructure and equipment will last longer now that corrosion caused by H2S has been neutralized.

- Our non-triazine scavengers are not based on commodity-priced products, so our prices are protected and are less impacted by external factors such as freezes and industrial raw material shortages.

Field Results and Performance

Triazine vs. Non-Triazine: Key Considerations

In conclusion, both triazine based H2S scavenger and-non triazine H2S scavenger options have their benefits and are the go-to alternatives for oil and gas treatment. However, one may be better than the other depending on the specific characteristics of the product that needs to be treated. For more information on triazine-based scavengers for natural gas operations, check out our detailed overview here. If you’re looking for the right H2S scavenger solution for your company, feel free to contact us! You can also read more about how switching to Pro3® can be the game-changer for your operations in our detailed comparison of triazine versus non-triazine treatments here

Sources:

https://www.sciencedirect.com/science/article/abs/pii/S1875510017304559