What are Mercaptans and where are they found?

Methyl mercaptan, or methanethiol, is a colorless, flammable gas that smells like rotten eggs and is present in many different ways in our environment. For example, onions, asparagus, oranges, and radishes are some foods that naturally contain mercaptans. Certain marine bacteria can also generate mercaptans, they are partly responsible for the marshy or stagnant smell in water. Due to its distinct smell, mercaptans can be helpful odorants to aid people in detecting the presence of other gases or chemicals since they can be noticed by humans in lower quantities. This is why mercaptans are added in low concentrations to natural gas.

Although commercially added mercaptans are helpful, naturally occurring mercaptans form in much higher concentrations and their presence may cause corrosion to production sites, health issues to personnel, and noxious discomfort to workers and communities that live close to where these afflicted hydrocarbons are processed, which includes crude oil and refined products. Because of these issues, there are oilfield chemical companies that provide odor control chemicals that not only eliminate the rotten -egg smell but also help with all mercaptans’ inconveniences.

In this blog, we will dive into how to deal with naturally occurring mercaptans and mercaptan odor control.

Why we need to treat Mercaptans.

Mercaptan odor control is one of the many aspects addressed when dealing with mercaptans. Aside from odor issues, mercaptans increase corrosivity, contribute to instability, and make it exceedingly difficult to meet product specifications. The presence of mercaptans along the oil production chain can create problems both from steel and alloys corrosion during storage and transportation, to odor complaints from neighbors.

This is why mercaptan removal is necessary in feedstocks and refined products.

Mercaptans vs. Hydrogen Sulfide (H2S)

While mercaptans are closely related to hydrogen sulfide (H2S) and may be efficiently handled with comparable methods, there are certain unique issues to be aware of:

- Detection levels for mercaptans are much lower than hydrogen sulfide, so it is way easier for mercaptans to cause complaints.

- Mercaptans are not as soluble in water as H2S. Water solubility is an important property of chemicals because it impacts how easily they will break down.

- Mercaptan molecule structures have a higher level of complexity than H2S molecules. Since mercaptans undergo additional steps in their biological breakdown, treating them may take longer.

- Although noxious at moderate levels, even high mercaptan levels are not fatal as compared to relatively low levels of hydrogen sulfide (H2S).

- Mercaptan molecules are more complex than H2S and are harder to break down. The simplest mercaptan is methyl mercaptan but chained/complex mercaptans are also common.

How to manage Mercaptans.

Our mercaptan scavenger, ProM®, is currently being used in multiple applications to reduce the presence of mercaptans. ProM® has consistently outperformed alternative chemistries for lower chain mercaptan removal.

How ProM® works at a glance:

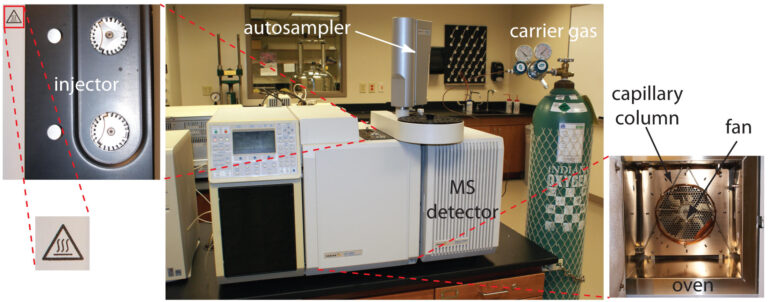

- First, a specialized lab analysis is made to determine the mercaptan levels and variety of mercaptan species present.

- Based on lab results, we determine the appropriate dosing of ProM® chemical.

- Introducing the product to the afflicted crude oil or liquids at a point in the pipeline or vessel that has the most effective turbulence and contact time is critical.

- Lastly, a repeat test confirms that quality spec has been reached and the volume may continue to sales.

Remember, unlike H2S, mercaptans are overly complex branched sulfur-based hydrocarbon chains that require lab analysis to determine treatment approach. ProM® has been specifically engineered to use non-triazine/non-amine based chemicals, which makes it safe to be used in refineries.

Conclusion

When mercaptans are treated, crude oil commercial specs are achieved, and the crude may be sent to a refiner. Additionally, odor is controlled and neighborhoods downwind from the facilities will not be affected. And finally, the health and safety of the workers on locations is improved.

Whether you need mercaptan removal from natural gas, wastewater odor control, mercaptan removal from LPG, or from any other hydrocarbon, contact us to find solutions to mercaptan contamination. We have the mercaptan scavengers to satisfy your needs and we offer many more oilfield services for H2S and mercaptan treatment.

Sources

https://chem.libretexts.org/Courses/Northeastern_University/12%3A_Chromatographic_and_Electrophoretic_Methods/12.4%3A_Gas_Chromatography