DRY CATALYST AND REACTOR SYSTEM FOR NATURAL GAS APPLICATIONS, CONSISTENTLY MEETS PIPELINE QUALITY SPECIFICATIONS.

Q2 Technologies has brought to market Pro3® Nano, a proven non-triazine solid catalyst and engineered reactor system, designed to treat for Hydrogen Sulfide (H2S) in Natural Gas. When loaded into specially designed reactor vessels or retrofitted contact towers, the Pro3® Nano product can offer lower operating costs as compared to triazine scavengers or other solid bed media. With longer cycle times, allowing for fewer cleanouts, and less field personnel on hand to monitor on a daily basis, operations utilizing Pro3® Nano add value to reserves by increasing production of previously curtailed sour wells.

We identified Pro3® Nano because the solid media competitor base was simply not achieving pipeline quality specifications.

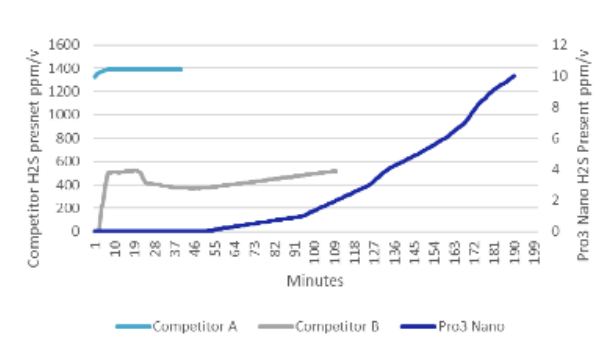

Pro3® Nano reactions were immediate and maintained 0 ppm for an extended period of time. When breakover did occur with Pro3® Nano, the process was gradual as compared to the others.

Pro3® Nano outperforms competitors significantly, as shown in this example lab trial. Samples were dosed at extremely high levels of H2S and Pro3® Nano maintained 0 ppm for a period of time and when breakover occured, it was gradual.

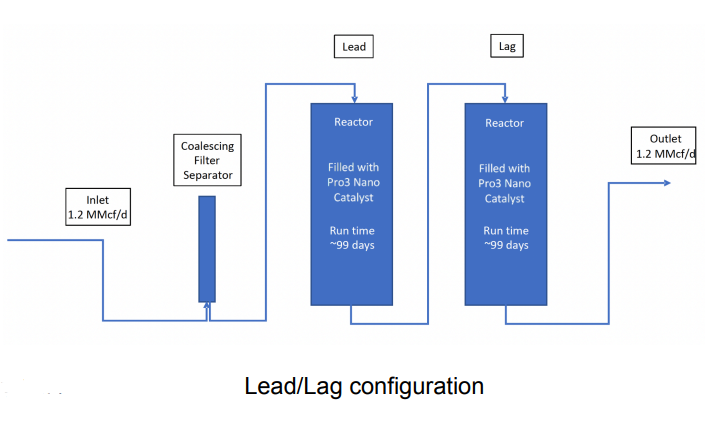

For the 1.2 MMscf/d example, we utilized a lead/lag configuration in our design. This setup included a coalescer upstream of the reactors which provided additional filtration. The lead/lag concept allows for continuous operations based on Q2 Technologies’ extensive field development program. Accounting for the expected breakover, the robust design of the lead/lag unit can be switched out so the lag reactor becomes the new lead reactor. The ability to swap reactors increases the bed life of the overall catalyst system.

For the 1.2 MMscf/d example, we utilized a lead/lag configuration in our design. This setup included a coalescer upstream of the reactors which provided additional filtration. The lead/lag concept allows for continuous operations based on Q2 Technologies’ extensive field development program. Accounting for the expected breakover, the robust design of the lead/lag unit can be switched out so the lag reactor becomes the new lead reactor. The ability to swap reactors increases the bed life of the overall catalyst system.

Lab tests show Pro3® GT and GT+ exceed 40% MEA triazine performance—no scale, no solids, superior temperature stability, seamless integration…

Replaced 40% MEA triazine at a Permian gas site—cutting usage by 45%, saving $3.8M annually, meeting pipeline specs, and eliminating…

Triazine replaced Sulfa-Check in a contact tower—achieving equal H2S removal with 50% less product, eliminating sulfur buildup, and removing the…