Q2 Technologies, a former subsidiary of Quaker Chemical which developed the MEA-Triazine scavengers used world-wide today, along with its Gulf Coast region distributor, Additive Direct Services have brought to market the Pro3® series of non-amine/non-triazine H₂S scavengers. The Pro3® series is the next generation of scavengers replacing MEA-Triazine in liquid hydrocarbon streams.

The Pro3® series is the result of a need to reduce fouling/corrosion created by amine based scavengers in refineries, production streams and crude oil terminals while improving H₂S removal performance compared to that of MEA-Triazine.

CHALLENGES

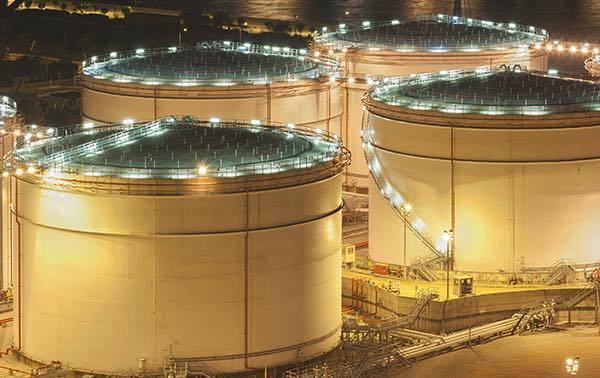

- Two 100,000 barrel inland collection crude oil storage tanks were being injected with up to 500 GPD of 40% MEA-Triazine.

- Approximately 150 trucks unloaded daily at the terminal with H₂S levels ranging from 30 ppmv to 25,000 ppmv.

- A high level of H₂S in collection tanks was still observed after triazine injection and required the customer to have expensive independent H₂S monitoring done followed up with additional treatment and delays.

SOLUTION

- Pro3® was recommended to substitute 40% MEA-Triazine

scavenger and to reduce chemical cost and logistics. - An injection system consisting of a single 6,000 gallon ISO tank with automated pumps replaced a system of 5 individual tote tanks being used to inject 40% MEA-Triazine.

RESULTS

- Storage Tank H₂S level using MEA-Triazine: > 10 ppmv

- Storage Tank H₂S level using Pro3®: <1 ppmv.

- Approximately 3 million barrels of EFL/EFR/WTI

are treated monthly with Pro3® series. - Chemical consumption was cut 80% compared to the 40% MEA-Triazine resulting in:

– Deliveries cut by 75% translating into increased personnel productivity.

– $35,000 per month reduction in chemical cost. *Will vary on application requirements - The need for H₂S monitoring personnel was eliminated resulting

in additional savings. Spot checks and daily electronic monitoring

are now sufficient to maintain a safe environment. - On-site bulk storage of chemical resulted in logistics and freight costs.

TAKE-AWAYS:

- >$35k per month chemical savings.

- Deliveries cut 75%.

- Chemical use cut by 80%.

Related Case Studies

Crude Oil & Liquids - Triazine

Amine Treater Regenerator Vent Scrubber

- H2S level reduced so that air can be discharged into atmosphere using Triazine.

-This continuous system has produced substantial economic benefits for the customer.

Crude Oil & Liquids - ProM®

Mercaptan Reduction in Condensate Splitter Feedstock

- ProM® Chemistry allowed customer to meet mercaptan specifications that MEA-Triazine was unable to reach.

Crude Oil & Liquids - Pro3®

H2S Removal in Crude from Marine Tankers

- $10K per month chemical savings by using Pro3®

- Deliveries cut by 50%

- Millions of barrels treated and hundreds of tankers and barges in spec.