SLUDGE TREATMENT FOR FOOD PROCESSOR

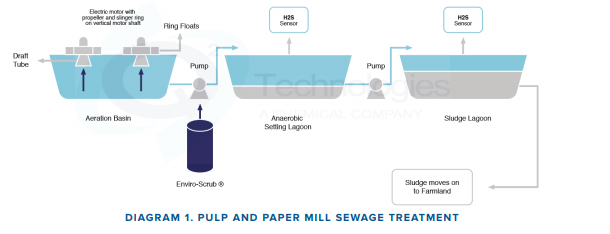

A large food processor treated 100,000 gallons of wastewater per day. The system consists of an aeration basin, anaerobic settling lagoon, and sludge lagoons as shown on Diagram 1. The system operated without chemical treatment. The customer has considered several treatment options including ferric chloride. Odors from the lagoons led to complaints from neighbors as far as half a mile away. The bad odors smelled like rotten eggs with an underlying odor associated with organic decay.

Because the sludge was spread on farmland, the use of heavy metal salts for odor control was not practical. The use of oxidizing agents such as potassium permanganate and hydrogen peroxide were also considered, but because the organic level in the plant’s wastewater was high, these were not cost effective.

Enviro-Scrub® eliminated H2S odors in a suburban wastewater system—ending community complaints, cutting labor costs, and outperforming ferrous sulfate in long-term…

Enviro-Scrub® Bio eliminated H2S formation at a Texas lift station—reducing 280 ppm to zero by altering bacterial activity, outperforming ferric…