Addressing H2S/Mercaptans in Crude Oil: Treatment Options at the Wellhead, Terminal, or Port.

– FAQs from Various Midstream Companies.

What challenges do H2S and mercaptans pose for midstreamers?

Commercial Challenges

- Pipeline and terminal shut-ins.

- Quality deducts (lower product value).

- Demurrage charges due to delays in handling contaminated crude.

Operational & Safety Concerns

- Health risks: H₂S is toxic and poses serious safety hazards for workers.

- Corrosion issues: Sulfide compounds can damage pipelines, tanks, and infrastructure.

- Operational disruptions: Requires treatment, monitoring, and sometimes halts in flow.

Causes of H₂S/Mercaptans Formation

- Souring of shale plays: Longer production periods increase sulfide compound presence.

- Brine/water seepage: Water sources enter production horizon, activating microbial activity.

- Microbial activity: Revitalized or introduced microbes generate H₂S.

- Post-production contamination: Tanks and pipes can act as incubators, accelerating H₂S production.

Can blending solve sour crude problems?

One frequently asked question is whether blending can resolve sour crude problems. While adding sweet crude to get into pipeline spec can partially address the issue, depending on the concentration of H2S or mercaptan levels, there might not be enough local volume to acquire for blending to reach a commercially acceptable threshold. And more importantly, it may not be economic to purchase that much blend stock. Chemical treatment is by far a more economic avenue.

Regardless of how sulfur compounds started showing up, if blending is not the first step in solving the issue, treating it chemically is the next logical step. Addressing the issue at the earliest known location is critical to mitigate long-term exposure risks to personnel and assets. By limiting exposure, you can extend the lifespan of your assets without being exposed to the side effects of sulfur corrosion.

Why treat H2S after separation, not downhole?

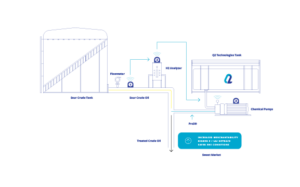

Where along the midstream chain should treatment happen?

How can ports provide a final opportunity for treatment?

Lastly, treating before or directly onto a crude oil vessel at the port presents an opportunity for a final polishing treatment. Movements at the port are the final points along the midstream sphere of influence and provide an opportunity to offer the shipper a bit of insurance before proceeding to other markets that may have extremely tight parameters for meeting H2S, mercaptan, and sulfur concentration levels.

Okay, but back to blending: when can it be implemented correctly? When the desired outcome is to reach as close to zero as possible, chemical treatment may have done the “heavy lifting” up to this point. In such cases, it may be worthwhile to consider blending feed stock as a final option. It may be a better use of allocations to introduce blending after chemical treatment has successfully removed a substantial portion of the issue. Incorporating a blending component into the overall mix may open opportunities for increased throughput.

What has been a big issue affecting your system? Feel free to reach out to us to share.