In oil and gas midstream operations, Lease Automatic Custody Transfer (LACT) units play a crucial role in ensuring the accurate measurement and transfer of crude oil from production sites to pipelines or storage facilities. LACT units automate the process of measuring, sampling, and transferring crude oil while meeting regulatory and contractual specifications.

How a LACT Unit Works

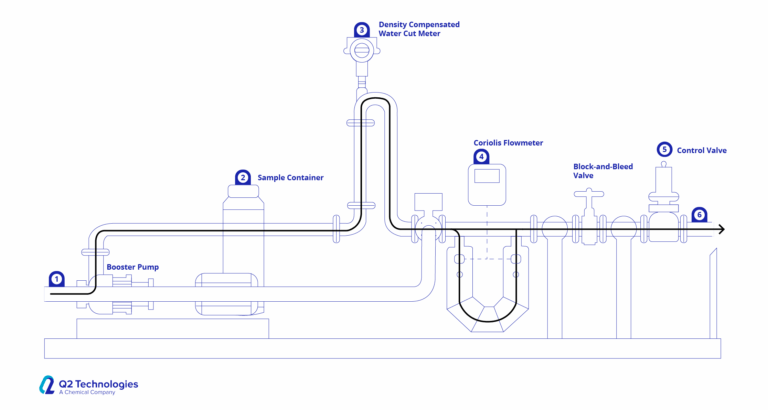

A LACT unit is a self-contained system designed to measure and transfer crude oil efficiently while ensuring that only merchantable-quality oil enters the midstream network. The process follows several key steps:

- Oil Enters the LACT System: Crude oil is pumped into the LACT unit from a booster pump.

- Sampling: a sample pot collects a representative sample of the crude for quality analysis. Sampling depends on the frequency of maintenance.

- Filtration & Water Separation: Initial filtration removes debris and free water separation helps prevent excessive water from entering the pipeline. Not all LACTs may be equipped with dedicated filtration or separation, rather, if the water detection system registers high BS&W, it would automatically divert the entire volume back to the heater treater for further separation.

- Measurement: The Coriolis meter provides highly accurate mass and volumetric flow measurement.

- Quality Verification: The unit checks for unacceptable levels of water, sediment, or contaminants that could impact the oil’s marketability.

- Transfer to Pipeline: If the oil meets specifications, the control valve automatically opens and allows oil to flow to the pipeline, if not, it may be bypassed or rejected.

Learn more about buildup and flow issues in crude systems in our Scale 101: Part 1 article.

The Role of the Coriolis Meter

The Sample Pot and Its Importance

How a LACT Unit Works

A LACT unit is a self-contained system designed to measure and transfer crude oil efficiently while ensuring that only merchantable-quality oil enters the midstream network. The process follows several key steps:

- Excessive Water Content: If the crude contains high levels of BS&W (above pipeline specifications, often 0.5% or less), it must be treated or rejected.

- H2S Presence: Hydrogen sulfide (H2S) is a hazardous gas that makes crude oil dangerous to handle and transport. If detected beyond acceptable limits, the oil may require additional treatment or be rejected outright (learn more about our H2S removal products).

- Iron & Sediment Contamination: These can cause pipeline corrosion, fouling, and equipment damage, making the oil non-merchantable.

- Meter Calibration Issues: The Coriolis meter must be regularly calibrated to ensure measurement accuracy.

- Valve & Pump Failures: Mechanical failures in the system can lead to improper transfers, inaccuracies, or downtime.

Crude Oil Quality and Marketability

For crude oil to be considered merchantable and accepted into midstream infrastructure, it must meet specific quality parameters. Common contaminants that lead to rejection or bypassing include:

- Water (BS&W exceeding limits): Excessive water reduces crude value and requires further processing.

- Hydrogen Sulfide (H2S): High levels pose safety hazards and can lead to pipeline corrosion.

- Iron & Sediment: Particulate matter can damage refining equipment and pipelines.

- API Gravity Variations: Crude must meet API gravity specifications to ensure consistency in processing.

Conclusion

LACT units are vital in ensuring accurate, efficient, and safe custody transfer of crude oil in midstream operations. With key components such as the Coriolis meter for precise measurement and the sample pot for quality verification, these systems help enforce crude oil specifications. However, challenges such as excessive water, sediment, H2S, or other contaminants can lead to rejection, emphasizing the importance of monitoring and maintaining oil quality before transfer. Proper operation, maintenance, and monitoring of LACT units ensure compliance with pipeline requirements and help maximize the value of crude oil in the marketplace.

Need help with H2S removal or midstream measurement challenges? Contact Q2 Technologies to speak with our experts.