The natural gas industry faces a constant challenge: removing harmful hydrogen sulfide (H2S) from its product for safe and efficient transportation. Traditionally, triazine has been the go-to solution, but recent innovations have sparked a question – are there better options available?

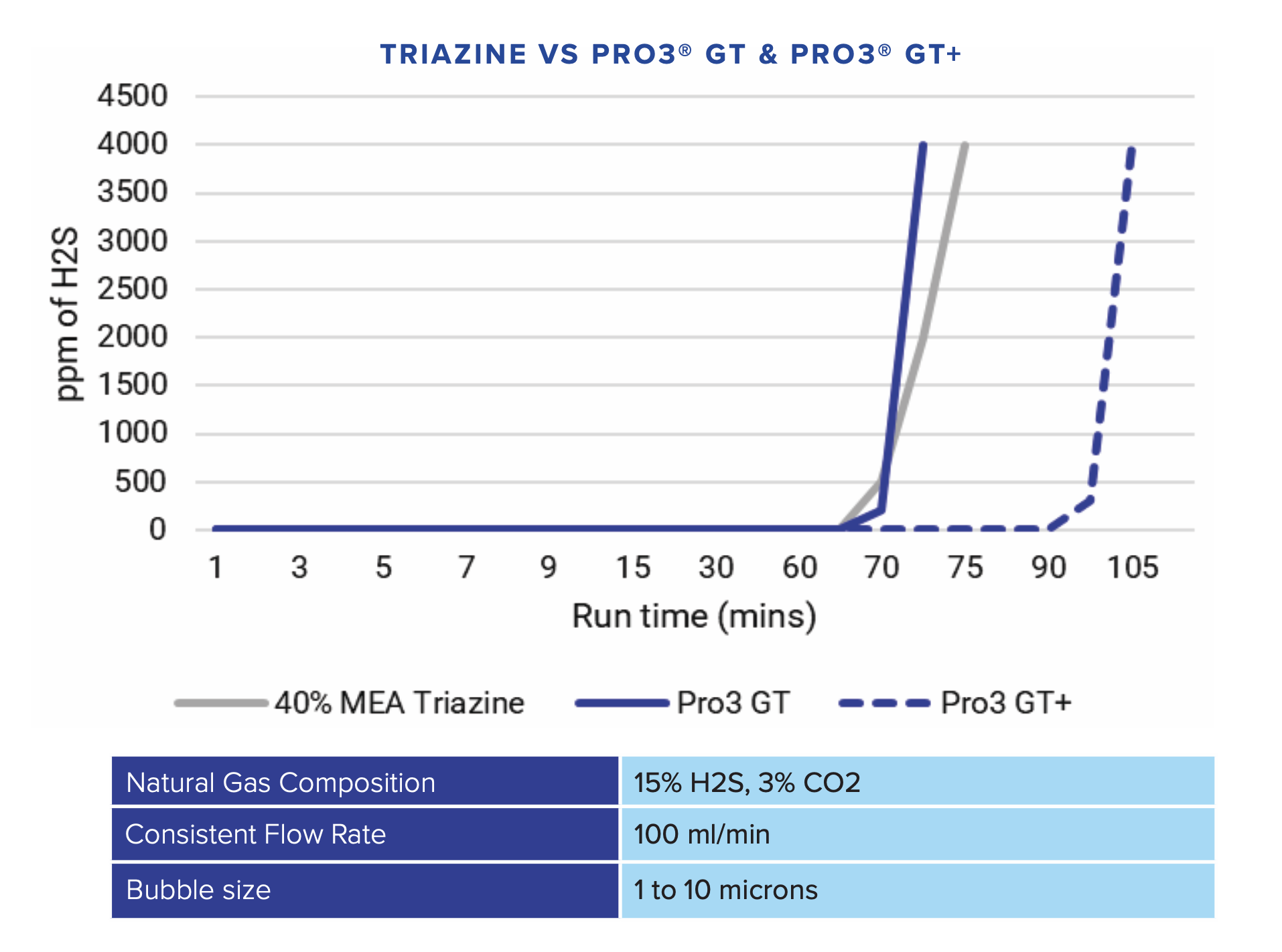

Our team at Q2 Technologies made a laboratory investigation to compare the performance of triazine, Pro3 GT, and GT+. This wasn’t just about finding alternatives, it was about discovering solutions that could streamline operations and overcome the limitations of existing methods.

Performance in H2S Removal Efficiency

We first pitted 40% active MEA triazine against Pro3 GT, its chemically similar counterpart designed as a direct substitute. Both performed neck and neck in H2S removal efficiency until the point of breakthrough. As expected, Pro GT+, as a concentrated form of Pro3 GT, was able to last longer in this controlled application.

Beyond Efficiency: The Challenge of Solids

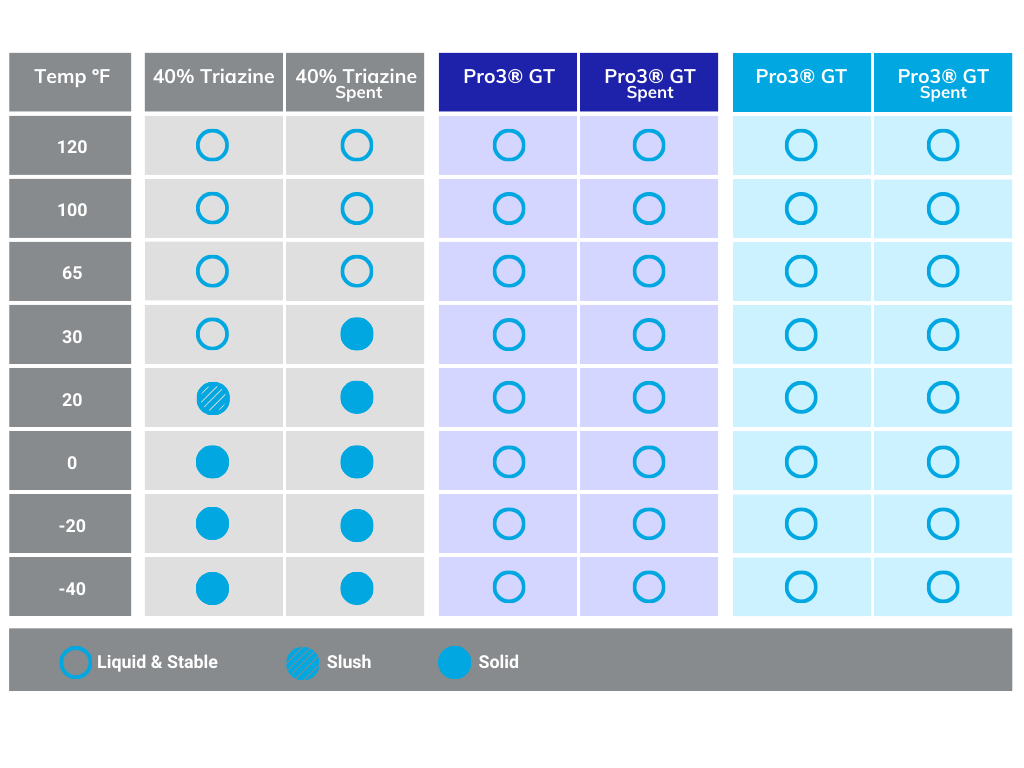

When the Temperature Drops:

Final Verdict: Are Pro3 GT and GT+ the Future?

While this study offers a glimpse into the potential advantages of Pro3 GT and GT+, it’s crucial to remember that the real world presents a complex landscape. Field conditions and economic factors like cost and treatment longevity also play a vital role in the decision-making process.

However, the impressive performance of Pro3 GT and GT+ in H2S removal efficiency, resistance to solid formation, and cold temperature resilience suggests they can be strong contenders in the H2S removal arena. We encourage you to explore further, consult with professionals, and consider all factors before embarking on your own journey towards a streamlined and efficient H2S removal solution.

Contact us to learn more or to speak with a specialist about your H2S treatment needs.