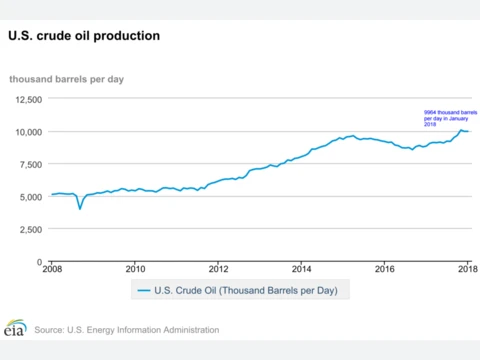

Texas ports have grown tremendously and continue to expand its capacity. Particularly, the port of Corpus Christi and the port of Houston have invested heavily to better connect oil producers with markets around the world. See regional port activity driving Texas oil exports. Oil, gas and NGL production in the US have transformed the country in a net exporter. U.S. producers now export between 1.5 million and 2 million barrels of crude a day, which could rise to about 4 million by 2022.

The nation’s output is expected to account for more than 80 percent of global supply growth in the next decade, according to Paris-based International Energy Agency.

This growth accompanies investment in infrastructure throughout the region though challenges remain to eliminate bottle necks in transportation. A new marine terminal facility along the Texas Gulf Coast to export U.S. crude, condensate and refined petroleum products has been approved by the Port of Corpus Christi Commission.

The commission last week approved a lease agreement with Corpus Christi Infrastructure LLC (CCI) for about 55 acres of land on the north side of the Corpus Christi ship channel in the inner harbor for a new oil dock. From 2016 to 2017, the port’s oil exports have increased 267 percent, from an average of 83,488 barrels per day to 306,334 barrels per day. With increasing exports, Q2 Technologies® continues to expand its capabilities—discover our developments

For Q2 Technologies®, there have been many opportunities to help midstream clients treat cargo vessels, oil before being sent in pipelines and in terminals. Contact us, we will be delighted to help remove hydrogen sulfide from oil in different applications and get more for your barrel.