Terminal tanks are critical assets in the midstream oil and gas sector. These massive structures store millions of barrels of crude oil and other hydrocarbons at key logistics hubs across the globe. But what exactly is going on inside these tanks?

In this blog, we take a look under the hood — or rather, under the roof — of a crude oil terminal tank to better understand its internal components, operational purpose, and why each element matters for safety, efficiency, and product integrity.

What Is a Terminal Tank?

A terminal tank, often located at storage terminals near refineries, ports, or centralized locations in the field—commonly known as terminals or terminal hubs—is designed to hold large volumes of crude oil or refined products. These tanks serve as buffers in the oil supply chain, enabling reliable transportation, blending, or further processing. In terms of crude oil movement, once a barrel enters a tank, its movement can temporarily stop to allow for volume accumulation. This is particularly important for FERC-regulated pipelines, which require barrels to “come to rest” before crossing certain state or federal boundaries.

Did You Know?

Terminal tanks are deeply tied to the development of the U.S. pipeline system and federal regulation. When longer pipelines were first being developed, crude oil sources were often far from refineries, which tended to be near population centers. As pipelines began crossing state lines to bridge that gap, the federal government had to step in to establish a common regulatory framework. This ensured that states could operate under mutual standards and that smaller or less-established shippers could access markets without being pushed out by larger players. This need led to the formation of the Federal Energy Regulatory Commission (FERC). Today, FERC continues to oversee aspects of crude oil transportation and tank terminal design as part of the interstate system.

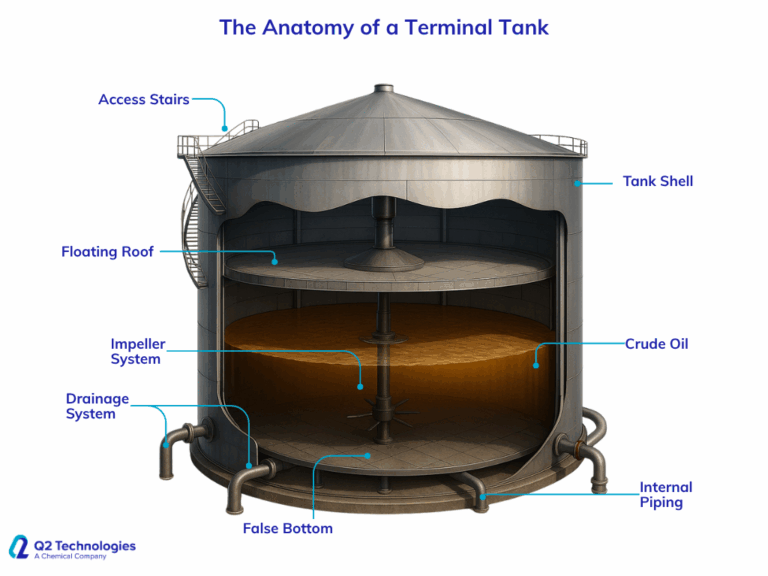

Cross-Section of a Terminal Tank: Key Components

Here’s a breakdown of the critical internal components typically found in a crude oil terminal tank:

1. Floating Roof

- Function: Sits directly on top of the oil surface, rising and falling with product level.

- Purpose: Minimizes the vapor space above the liquid, reducing volatile organic compound (VOC) emissions.

- Types: External floating roof (EFR) and internal floating roof (IFR), the latter being enclosed by a fixed roof to reduce weather impact.

- Structure: A cylindrical steel wall that contains the product.

- Design: Built to API 650 standards, often over 100 feet in diameter and 40+ feet tall.

3. Impeller or Mixing System

- Role: Maintains homogeneity in the stored product, especially important for stabilized crude blends.

- Types: Jet mixers, spargers, or mechanical agitators, depending on tank size and content type.

4. False Bottom (Optional)

- Purpose: Allows for heating coils or drainage channels beneath the actual storage floor.

- Benefit: Prevents water accumulation and sludge settling, improving product recovery and reducing corrosion risk.

5. Drainage System

- Includes: Internal drains and sump systems.

- Function: Facilitates removal of water bottoms and sediment; critical for tank maintenance and cleaning operations.

6. Internal Piping

- Inlet/Outlet Lines: Control product entry and exit.

- Recirculation Lines: Allow product mixing or transfer to other tanks.

- This can be as simple as a transfer pump moving crude from one tank to another. More advanced systems can portion certain volumes to a fully manifold system.

- Vapor Recovery Lines: Connect to vapor control systems to meet environmental regulations.

7. Access Ports and Manways

- Usage: Entry points for inspection, sampling, or maintenance.

- Safety:Equipped with gas detection and fall protection features for confined space entry compliance.

- Control Room:Every modern tank terminal has a dedicated team of professionals responsible for coordinating with on-site personnel. These control room operators may be located on-site or, more commonly, at a remote location. They are typically staffed 24 hours a day and work in shifts to ensure continuous operation without downtime. Operators may have override authority based on multiple redundant readings—such as pressure, temperature, and volume—to help prevent human error in the field. Additional measures are often taken to keep these control rooms secure, including hardening their network connections.

Why This Matters: Operational and Safety Implications

Understanding the anatomy of a terminal tank isn’t just technical curiosity — it’s critical for:

- Product integrity: Uniform storage reduces stratification and contamination.

- Regulatory compliance: Emission controls and safe venting systems are essential for meeting environmental standards.

- Maintenance planning: Access to internal systems allows for proactive corrosion monitoring and efficient cleaning.

- Safety and incident prevention: Proper design minimizes risks of tank overfills, vapor ignition, and structural failure.

The Role of H2S Scavenging in Tank Operations

Many crude oils — especially sour crudes — contain hydrogen sulfide (H2S), a toxic and corrosive gas. Inside terminal tanks, H2S can accumulate in the vapor space or be released during tank breathing.

That’s why integrating H2S scavenging solutions is crucial for:

- Worker safety during sampling or maintenance

- Equipment longevity by reducing corrosion risks

- Compliance with OSHA and EPA regulations

At Q2 Technologies, our non-triazine H2S scavengers are widely used across terminals to ensure safe, effective crude storage and handling.

Final Thoughts: Every Tank Tells a Story

Terminal tanks may look simple from the outside, but inside, they are complex systems engineered for performance, safety, and reliability. Whether you’re planning storage capacity, managing emissions, or optimizing product handling, understanding tank anatomy is foundational to smarter operations.

Want to learn more about tank treatment technologies or H₂S mitigation at your terminal?

Contact Q2 Technologies to speak with our experts.