2021 was a rainy year, ranking as the third most active hurricane season in history as well as the third costliest, with a total of nearly $81 billion in damage. Hurricane Ida by itself, swept through Louisiana and much of Mississippi, forcing the shut down of refining operations and oil production in the Gulf of Mexico, and had a cost of over $75 billion in damages. Ida disrupted much of the chemical supply chain when it hit, leading to H2S scavenger raw material shortages.

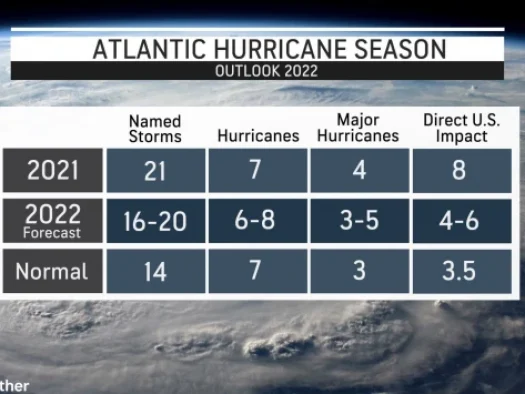

[For 2022 ] An early outlook (…) forecasts an active North Atlantic hurricane season, which could affect oil and gas supply due to shut-in production at platforms in the U.S. Gulf of Mexico (HART Energy, 2022).

As meteorologists forecast an active hurricane season, producers, midstreamers, refiners, and chemical treatment companies must prepare for what could be a replay of last year’s heavy storms. For Q2 Technologies, it is essential for us to be ready; we know that these events can cause driver shortages, road/route closures, and production shut-ins at plants, which makes it extremely difficult to manufacture, deliver, and consequently treat oil and gas production. Despite hurricane season in full swing (the season actually starts June 1st lasting until November 30th), production at the wellhead does not stop, therefore Q2 Technologies is making the necessary arrangements to plan accordingly so our critical product is available during this uncertain time.

As a trusted chemical provider for our clients, we ensure that sufficient levels of our H2S removal products are securely stored close to our clients’ assets in anticipation of hurricane season.

We’ve taken the necessary steps to manufacture a sufficient amount of additional product and have coordinated ahead of time with our multiple trucking logistics partners to get product to location or storage. We stage at least 1 month worth of chemical inventory in West Texas and the Texas coast to ensure that any weather related supply disruptions will not jeopardize our delivery capability.

How do we manage to continue to deliver our product when a hurricane is imminent? This is actually a very simple answer: by being prepared, by manufacturing the product in advance, and before production is threatened. Having sufficient raw material from a diversified supplier pool at multiple manufacturing sites mitigates our production risk. Having multiple manufacturing sites allows us to deliver to multiple basins. We have been very strategic in our partnerships over the last 21 years, seeking partners with the highest integrity, and facilities with world-class blending that have easy access to major highways and thoroughfares.

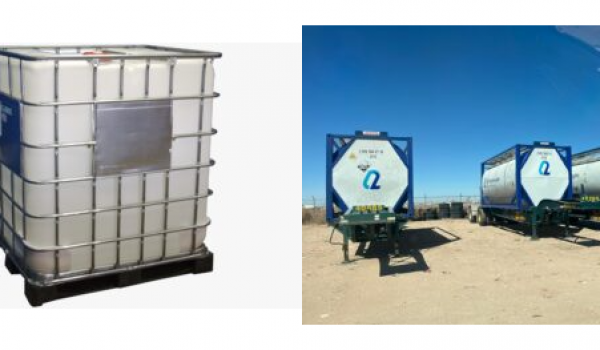

Adaptability is also fundamental, depending on conditions, locations and our clients’ needs, we provide a wide range of different vessel formats, allowing our product to be ready for shipment in containers of all kinds of shapes and sizes: ISOs, Drums, and Totes.

Working at multiple manufacturing sites and being prepared with a fleet of trucks and carriers is critical. Multiple carriers are key for successfully delivering chemical loads. If, for any reason, one is delayed, another one may come to the rescue; partnering with different trucking companies has allowed us in previous years to successfully deliver our product and treat our clients’ crude oil and gas in a regular manner.

In conclusion, to seamlessly continue treatment in multiple basins while hurricane threats arise, we have implemented a ‘planning ahead’ mindset. Learn more about how Q2 Technologies is increasing inventory and logistical capabilities amid the 2022 hurricane season to ensure uninterrupted chemical supply for our clients

- Multiple raw material providers

- Several manufacturing sites close to major highways and thoroughfares

- Diverse vessel sizes

- Multiple transportation services

- And stockpile field ready inventory

If you’re interested in our multiple H2S removal products, we’d be happy to have a chat with you! Contact us or give us a call +1 832-328-2200.

Sources:

https://www.api.org/news-policy-and-issues/hurricane-information/hurricane-preparation