The Laurence Reid Gas Conditioning Conference is the principal forum for new ideas, developments, and operations for preparing and purifying natural gases and other fuels for market. This year, it took place February 22nd-25th 2021 and we are happy to share with you the content of our virtual presentation from this week. We presented the results of the first commercial application of our new regenerable process, Pro3® Nano chemistry and experiences.

Our presentation was called “Experiences in the First Commercial Application of Regenerable Nanotechnology Chemistry and Process for Hydrogen Sulfide Removal in Natural Gas” was a well attended event where the public asked many important questions.

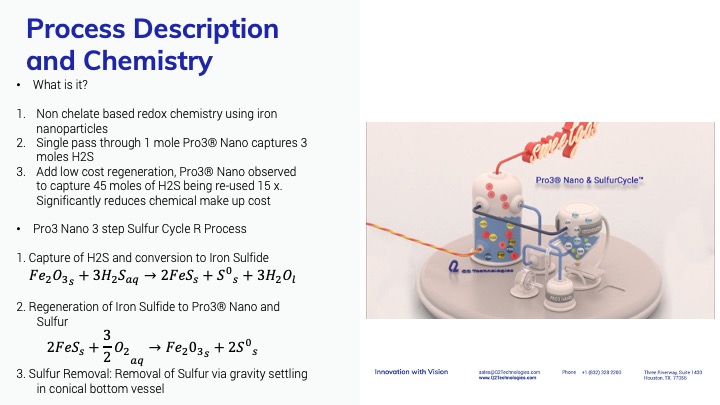

Please go through the slides and contact us to discuss further how we can help you treat your gas with our regenerable process with Pro3® Nano.