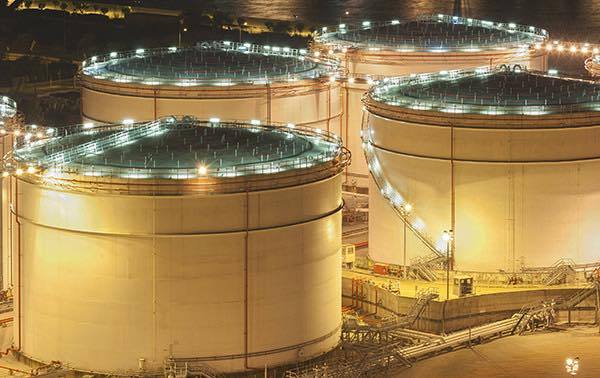

Revolutionize your H2S removal process with Pro3®, the innovative non-triazine, non-amine H2S scavenger. Pro3® permanently removes hydrogen sulfide (H2S) from crude oil and liquid hydrocarbon applications, allowing you to meet pipeline specifications and increase the value of your barrels. Our solution offers significant cost savings by reducing chemical usage by 50-75% compared to traditional methods like glyoxal and MEA triazine. Pro3® is also safer and protects your assets, while providing scalability from wellheads to terminals and VLCCs.

Q2 Technologies leads the industry in pairing real-time H2S testing with precise H2S dosing treatments – all automated.

We remove H2S from millions of barrels with Pro3®. Immediately remove H2S from crude oil, meet pipeline spec.

Lower your lease operating expense, reduce chemical use by 50-75% as compared to glyoxal and MEA triazine

Pro3® non-amine scavenger increases the value of your barrels, leads to better market optionality

Pro3® provides safety & protects assets

1

2

3

Immediately remove H2S from crude oil and meet pipeline spec.

Pro3® is used by Producers, Midstreamers, and Traders and approved by major terminals and pipelines.

It is a non-amine and non-glyoxal H2S removal technology, making it safe for refineries and pipelines.

Triazine-based treatment has been the go-to solution for many Producers, Midstreamers, and Refiners. But for some, implementing new technology such as non-triazine products has positively impacted their operations and has lowered their costs in their H2S removal efforts. Is one better than the other? That all depends on your use case and process conditions. Read more details here in our Triazine Vs. Non-Triazine blog.

We treat millions of barrels of crude and condensate and are successful in H2S removal to less than 10 ppm.

H2S in the oil and gas industry is very common. H2S removal products with Pro3® allows for Producers/Midstreamers to have safer operations and increase reliability. H2S compliance allows for safer transportation via pipelines which also allows for a better netback price of the barrels.

– $10K per month chemical savings by using Pro3®

– Deliveries cut by 50%

– Millions of barrels treated and hundreds of tankers and barges in spec.

– ProM® Chemistry allowed customer to meet mercaptan specifications that MEA-Triazine was unable to reach.

– H2S level reduced so that air can be discharged into atmosphere using Triazine.

-This continuous system has produced substantial economic benefits for the customer.