Hydrogen sulfide (H2S) is a major concern in upstream crude oil and natural gas production, midstream transport, and downstream refining. It’s a colorless gas with a distinct rotten egg odor, but its dangers go far beyond its smell. At high concentrations, H2S is highly toxic, corrosive, and explosive, requiring operators to implement efficient removal strategies to protect personnel, equipment, and product quality.

While the fundamental methods of H2S removal have been established for decades, the industry is continuously evolving. Operators today must balance performance, cost efficiency, environmental impact, and regulatory compliance. In this blog, we’ll break down the latest insights into H2S removal in Natural Gas, covering traditional and emerging technologies, their advantages and limitations, and what the future holds for H2S management.

As Natural Gas production grows, effective H2S management becomes increasingly important. Let’s take a closer look at how emerging technologies are addressing these challenges in the Natural Gas sector.

Why H2S Removal is Critical in Natural Gas

The presence of H2S in hydrocarbon production can be present in crude oil, natural gas, and produced water, but today we’re focusing on H2S in Natural Gas, which, when present creates multiple challenges:

H2S is extremely toxic. According to OSHA and other health related regulatory agencies which tend to focus on permissible levels for safe work conditions, less than 20 ppm is generally accepted to be safe. At concentrations above 100 ppm, it can cause severe respiratory issues, and at 700 ppm or higher, it can be fatal in just a few breaths. Ensuring proper removal before transport or processing reduces worker exposure risks and improves site safety.

Image Source: https://en.gazdetect.com/gas-information/h2s-hydrogen-sulfide-gas-detector/ https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.1000TABLEZ2

2. Corrosion & Infrastructure Damage

H2S reacts with metals, leading to sulfide stress cracking (SSC) and pipeline corrosion. Uncontrolled H2S levels can reduce the lifespan of equipment and increase maintenance costs. Proper removal mitigates these risks and ensures long-term asset integrity.

Environmental and safety regulations impose strict limits on H2S emissions and pipeline transport specifications. For example:

- The EPA regulates H2S emissions , along with 118 other contaminants, under the Clean Air Act due to its role in acid rain and air pollution.

- Pipeline gas transmission standards (such as those set by the GPA Midstream Association) limit H2S to as low as 4 ppm to prevent infrastructure damage and ensure downstream compatibility.

H2S reacts with metals, leading to sulfide stress cracking (SSC) and pipeline corrosion. Uncontrolled H2S levels can reduce the lifespan of equipment and increase maintenance costs. Proper removal mitigates these risks and ensures long-term asset integrity.

Overview of H2S Removal Technologies

There is no one-size-fits-all approach to H2S removal. The best method depends on factors like gas composition, flow rate, temperature, and operational constraints. Below, we break down the most widely used removal technologies:

1. Amine Gas Sweetening (Regenerative Absorption)

2. Non-Regenerative H2S Scavengers (Chemical Scavenging)

- Scavengers chemically react with H2S, forming stable, non-volatile byproducts.

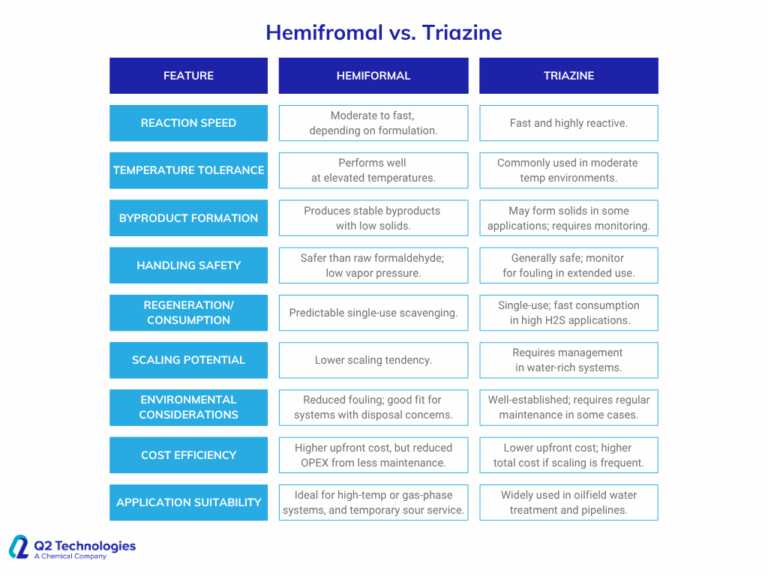

- The most common scavenger type is triazine-based, but newer formulations are emerging to reduce operational issues like scaling.

Advancements in Scavengers:

New scavenger technologies are improving efficiency, reducing environmental impact, and addressing common industry challenges. Traditional triazine-based scavengers, while effective, can lead to issues such as scaling, high chemical consumption, and increased wastewater treatment costs.

At Q2 Technologies, we’ve developed innovative H2S scavengers that outperform conventional options by providing:

- Non-Triazine Solutions – Pro3® GT Series: Our Pro3® GT non-triazine scavengers eliminate common byproduct issues like scale buildup in pipelines and production equipment. This results in cleaner operations, reduced downtime, and lower maintenance costs.

- Enhanced Efficiency & Cost Savings: Our scavengers are designed for optimal performance, requiring lower chemical dosages to remove H2S effectively. This translates to reduced operating costs and improved treatment consistency.

3. Oxidation & Catalytic Processes

Emerging oxidation and catalytic technologies are gaining traction due to their environmental benefits.

- Liquid Oxidation Systems: Convert H2S into elemental sulfur or sulfate compounds using liquid catalysts.

- Direct Catalytic Oxidation: Uses metal catalysts to convert H2S to sulfur or sulfur dioxide without generating large waste streams.

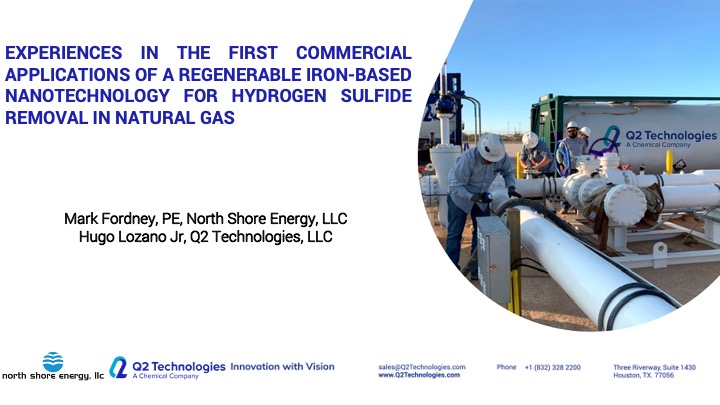

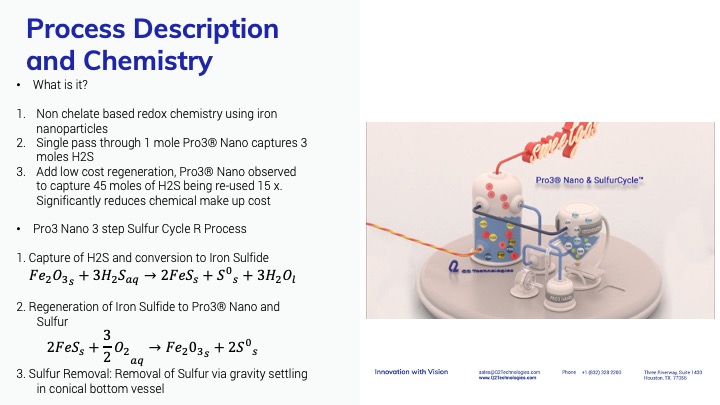

- Dry Scavenger Technology – Pro3® Nano: Unlike traditional liquid scavengers that require significant handling and disposal efforts,Pro3® Nanodry, solid-based H2S scavengerthat simplifies logistics, improves safety, and minimizes waste. This makes it an excellent choice for operators looking for a safer and more efficient alternative.

4. Claus Process (Sulfur Recovery)

- Used in large-scale gas processing, the Claus process converts H2S into elemental sulfur through controlled combustion and catalytic reaction stages.

- The recovered sulfur is often sold for industrial use (fertilizers, chemicals, etc.).

What’s Next for H2S Removal?

As the oil and gas industry evolves, so do H2S removal strategies. Several key trends are shaping the future:

Smarter H2S Monitoring & Control

- Real-time gas analysisallows operators to detect and adjust H2S treatment instantly.

- AI-driven automation is optimizing scavenger dosing to minimize chemical waste and reduce costs.

Lower-Impact Chemical Scavengers

- Non-triazine scavengers are eliminating concerns about pipeline scaling and wastewater treatment.

- Eco-friendly formulations are gaining popularity to meet stricter environmental regulations.

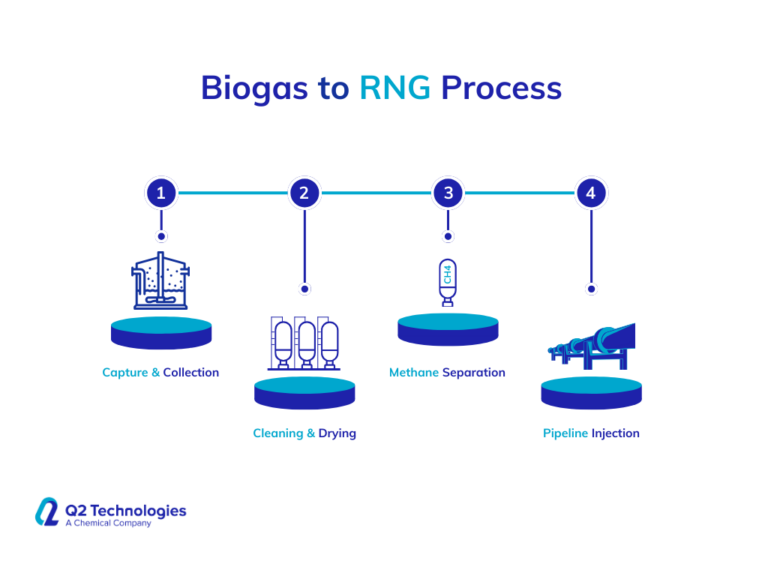

Sustainability & Sulfur Utilization

- Some operators are exploring new ways to repurpose recovered sulfur for commercial or industrial use.

- Lower-emission technologies are helping reduce the carbon footprint of H2S removal processes.

Choosing the Right H2S Removal Solution

Selecting the best H2S removal technology depends on:

- H2S concentration & gas flow rate – Higher concentrations often require regenerative systems, while lower levels may be best suited for scavengers.

- Operational constraints – Remote or offshore locations may favor non-regenerative solutions due to space limitations.

- Economic factors – Long-term operating costs, chemical consumption, and potential sulfur recovery benefits should be considered.

- Regulatory requirements – Compliance with safety and emissions regulations is essential when choosing a removal method.

At Q2 Technologies, we specialize in innovative, cost-effective H2S removal solutions tailored to today’s operational challenges. Whether you need reliable scavengers, advanced monitoring, or expert consultation, we help you optimize performance and compliance.

Need help with H2S removal? Contact us today to learn more about our customized solutions.

Final Thoughts

H2S removal is more than just a regulatory requirement—it’s a critical factor in worker safety, asset integrity, and product quality. As the industry shifts toward smarter, cleaner, and more efficient treatment solutions, staying informed on the latest advancements is key to maintaining a competitive edge.

By understanding the fundamentals and leveraging new technologies, operators can maximize efficiency, reduce costs, and ensure long-term compliance in an ever-changing regulatory landscape.