Why Inventory and Logistics Matter During Storm Season

Although the 2022 Hurricane Season has been fairly mild with only five named storms since the first week of September, the recent barrage of 1 in a 1,000 year weather events that has drenched a large swath of the US is proof that the weather systems are not to be trifled with. As a critical supplier of chemical products across the US to our clients in diverse industries, we are taking particular care to reinforce our logistics and product supply chain.

Therefore, Q2 Technologies is pleased to announce our latest logistics initiative of doubling our inventory at or near our Clients’ assets and enhancing our transportation capabilities.

Strategic Steps Q2 Technologies Is Taking

Q2 Technologies serves a wide range of industries including Oil & Gas, landfill biogas, dairy digesters, pulp and paper, and wastewater facilities. In preparation for potential weather disruptions, we’ve built strategic inventory stockpiles at secure facilities to maintain supply even during infrastructure setbacks. Additionally, we’ve enhanced our logistics with trusted partners, effectively doubling our transportation capacity.

Learn more about how we support industries with inventory solutions.

Increased Inventory Near Client Sites

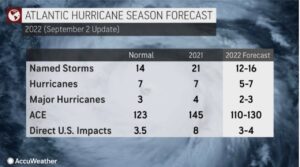

The recent 24–48-hour deluges of rain across the US in the past few weeks is yet another reminder of our changing climate and that damage does not just come from headliner storms like hurricanes and tornadoes but can come in a variety of isolated storms that are difficult to forecast with significant warning. While 2021 was a rainy year, ranking as the third most active hurricane season in history as well as the third costliest, with a total of nearly $81 billion in damage, experts are still holding that 2022 will be an active season albeit the forecast of named storms have lessened slightly. This is due to the fact that the US is still experiencing above normal La Niña effects which suppresses hurricane activity in the central and eastern Pacific basins, and ultimately bolsters the effects in the Atlantic basin, hence a wet 2022 season. If the La Niña conditions remain, we may see a steady line of named storms well into the fall and perhaps beyond the typical season of November 30th.

As meteorologists maintain their forecasts for an active season; producers, midstreamers, refiners, and chemical treatment companies must prepare for what could be a replay of last year’s heavy storms. For Q2 Technologies, it is essential for us to be ready; our latest initiative is a three-step approach:

We’ve taken the necessary steps to procure plenty of raw material, manufacture a sufficient amount of additional product and have coordinated ahead of time with our multiple trucking logistics partners to get product to location or storage. We have staged at least two months’ worth of chemical inventory in West Texas and at multiple locations near port locations along the Texas coast to ensure that any weather-related supply disruptions will not jeopardize our delivery capability. Further, we established additional trucking solutions in preparation for potential outages if the need arises.

Ensuring Continuity of H₂S Removal Solutions

We know that weather events can cause driver shortages, road/route closures, and production shut-ins at plants, which makes it extremely difficult to manufacture, deliver, and consequently treat oil and gas production. Therefore, Q2 Technologies has made the necessary arrangements to plan accordingly so our critical product is available during this uncertain time.

As a trusted chemical provider for our clients, we ensure that sufficient levels of our H2S removal products are securely stored close to our clients’ assets as the 2022 hurricane season continues.

Diverse Packaging and Shipping Solutions

Adaptability is also fundamental, depending on conditions, locations and our clients’ needs, we provide a wide range of different vessel formats, allowing our product to be ready for shipment in containers of all kinds of shapes and sizes: ISOs, Drums, and Totes.

Working at multiple manufacturing sites and being prepared with a fleet of trucks and carriers is critical. Multiple carriers are key for successfully delivering chemical loads. If, for any reason, one is delayed, another one may come to the rescue; partnering with different trucking companies has allowed us in previous years to successfully deliver our product and treat our clients’ crude oil and gas in a regular manner.

Contact Q2 Technologies

In conclusion, to seamlessly continue treatment in multiple basins while hurricane threats arise, we have implemented a ‘planning ahead’ mindset. Learn more about how Q2 Technologies is getting ready for hurricane season and ensuring uninterrupted chemical supply for our clients:

- Multiple raw material providers

- Several manufacturing sites close to major highways and thoroughfares

- Diverse vessel sizes

- Multiple transportation services

- And stockpile field ready inventory

If you’re interested in our multiple H2S removal products, we’d be happy to have a chat with you! Contact us or give us a call +1 832-328-2200.

Sources

Impacts of El Niño and La Niña on the hurricane season

1000 year floods? Let’s get real

How is the Natural Gas And Oil Industry Preparing?

Gulf of Mexico Oil and Gas Industry Faces Active Hurricane Season

Hurricane watch now in effect for Bermuda as Earl churns closer

What’s the best solution?

The best solution is whatever works best for your application. The main goal will always be H2S removal, but there are financial, operational, and commercial considerations that must be weighted.

- Have all KPIs (Key Performance Indicators) been identified and quantified?

- In doing so, are OPEX and CAPEX being optimized?

- Are the assets suffering from corrosion or over/under utilization?

- Is the hydrocarbon stream meeting commercial ppm requirements or thresholds?

These are some ideas to consider when choosing suitable treatment solutions, it not only depends on reaching H2S level requirements, but also on seeing how the scavenger affects your project as a whole. At Q2 Technologies we can help provide recommendations based on your specific needs, contact us and we’ll help you find exactly what you need to treat your sour gas.

Sources:

Impacts of El Niño and La Niña on the hurricane season

1000 year floods? Let’s get real

How is the Natural Gas And Oil Industry Preparing?

Gulf of Mexico Oil and Gas Industry Faces Active Hurricane Season

Hurricane watch now in effect for Bermuda as Earl churns closer